Advantages of Plate Heat Exchangers

The Advantages of Plate Heat Exchangers can be explained as follows; they are compact and efficient devices used in heat transfer, cooling and heating processes of liquids in industrial facilities. While these heat exchangers are preferred in industrial applications with their many advantages, they benefit businesses in various ways.

What are the advantages of plate heat exchangers?

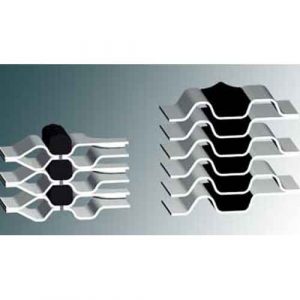

Special gasket design that prevents fluids from mixing:Firstly, the special gasket design of plate heat exchangers increases operational safety by preventing fluids from mixing with each other. Thanks to this special design, in case of any seal failure, fluids will leak out and this can be easily detected. This prevents possible dangers and provides a safe working environment for business owners.

Special gasket design that prevents fluids from mixing:Firstly, the special gasket design of plate heat exchangers increases operational safety by preventing fluids from mixing with each other. Thanks to this special design, in case of any seal failure, fluids will leak out and this can be easily detected. This prevents possible dangers and provides a safe working environment for business owners.- Low weight and small installation volume thanks to its compact design: Features such as compact design, low weight and small installation volume make plate heat exchangers a preferred option in industrial facilities. These exchangers take up 20-30% less space than tube exchangers of the same capacity, which means more efficient use of space for businesses. In addition, the smaller assembly volume facilitates the on-site arrangement of enterprises and results in lower investment costs.

- Thanks to full turbulence, high efficiency – low cost: Plate heat exchangers provide high efficiency and reduce operating costs. Thanks to its special design, high turbulent flow is created between the plates, which enables high heat transfer coefficients to be achieved. This high efficiency helps businesses save energy and reduce operating costs.

-

Advantages of Plate Heat Exchangers

Easy capacity increase: Thanks to their modular structure, plate heat exchangers allow easy capacity increase and enable businesses to quickly respond to their growth or changing needs.

- Lower maintenance costs: Plate heat exchangers are also very easy to maintain and provide lower maintenance costs. To access the heat transfer plates, simply removing the studs is sufficient, allowing maintenance to be carried out without the need for additional space. On the other hand, in tube type heat exchangers, an additional space equal to the volume used is needed to take out the tube bundle, and this requires additional cost and time.

- Long lifespan and durability: Finally, the long-lasting and durable structure of plate heat exchangers offers a long-term solution for businesses. Plate heat exchangers made of quality materials operate reliably for many years, which reduces the maintenance and repair costs of businesses.

In Conclusion, Advantages of Plate Heat Exchangers

Considering the Advantages of all Plate Heat Exchangers described above, plate heat exchangers have become an indispensable equipment for industrial facilities. By using these exchangers, businesses can increase energy efficiency, reduce operating costs and provide a safer working environment. Therefore, choosing plate heat exchangers can increase the competitive advantage of businesses and support their long-term success.