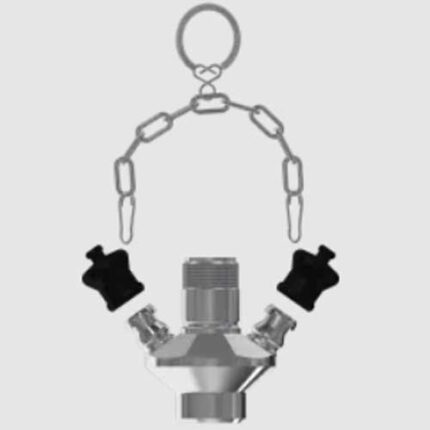

Discover precise control with sampling valves. Ensure accurate fluid sampling for quality assurance. Explore our range for your needs today. Sesinoks.

Showing all 3 results

Aseptic Keofitt Sampling Valve

Sampling Valve

Sterivalve Aseptic Radial Diaphragm Valves

Medical and food sampling valves

Medical and food sampling valves are special containers or tubes used for sample collection and transportation in related industries. Although they have functional similarities, they may be designed to meet different requirements in each industry.

- Medical Sampling Valves:

- Medical sampling valves are used to collect and transport biological samples (blood, urine, tissue samples, etc.) from patients.

- These valves are designed to ensure accurate collection of samples required for certain medical tests.

- They are often pre-sterilized and may have certain properties, for example they hold certain volumes or may be coated with certain chemicals.

- Food Sampling Valves:

- Food sampling valves are used in food production facilities, laboratories or inspection organizations.

- They are important for food safety and quality control. For example, samples are taken to analyze microbial contamination or chemical composition of products.

- Food sampling valves are designed to ensure that the sample is transported without spoiling or contamination, and they are usually sterilized.

The main purpose of both types of valves is to ensure that accurate samples are collected and stored appropriately for analysis. However, each can be customized to suit their industry requirements and sample types.

The basic functions of sampling valves are:

- Quality Control: Samples are taken to determine product quality at different stages of the production process. This is important to assess product compliance with specifications.

- Process Monitoring: Samples are taken to monitor the efficiency and stability of the process. For example, it is important to monitor parameters such as the composition, temperature or pressure of liquids.

- Testing and Analysis: Samples can be sent to the laboratory and subjected to comprehensive testing and analysis. This is done to determine the chemical, physical or biological properties of the product.

Sampling valves come in different types and features. Some common types are:

- Blind Plug Sampling Valves: These valves are used to take samples from a closed system. After the sample is taken, the valve is closed and communication with the system is interrupted.

- Sampling Valves with Manometer Connection: These valves enable pressure measurement while taking samples. This is useful for monitoring the pressure at the point where the sample was taken.

- Slide Plug Sampling Valves: These valves have an indicator that indicates whether the valve is fully open or fully closed during the sampling process. This is important for accurate sampling.

Sampling valves are widely used in industrial plants, laboratories, chemical processing plants, the oil and gas industry, the food and beverage industry and many other areas of application. These valves play a critical role in ensuring the safety, quality and efficiency of production processes.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions