Pumps moves the fluid under a certain pressure and thus enables the fluid to be transported from one place to another.

Showing all 14 results

Hyginox SE Hygienic Centrifugal Pumps

EFI Industrial Centrifugal Pumps

Dinfood High Capacity Centrifugal Pumps

DIN-FOOD Centrifugal Pumps, one of the High Capacity Food Processing Centrifugal Pumps, is a hygienic high capacity centrifugal pump capable of pumping up to 1000 m³/h, designed for use in the food processing, chemical and pharmaceutical industries.

It is mainly used in the beer, dairy and beverage industries and includes filtration processes. In addition, it can be used in some specific applications in the textile industry, chemistry, cosmetics and pharmaceutical industries.

RV Helicoidal Impeller Pump

Flexible Screw Pumps

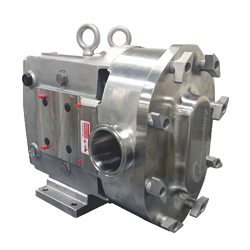

SLR Lobe Pumps

Rotary Piston Pump

KS Monopumps

Aspir Self-Priming Pumps

ASPIR Self-Priming Pumps are suitable for use in food processes, pharmaceutical and chemical industries. It is generally used for the transfer of products at temperatures close to the boiling point such as oil, wine, alcohol, acetone. Its main application is as a CIP return pump.

Gear pump with self-priming feature can transfer the product by sucking from a distance of 4-5 meters. It is extensively used in CIP systems, food applications and fluid transfers containing steam.A pump is a machine used to move fluids such as liquid, gas or mud from one place to another.

The pump can be designed in many different ways and be based on different principles. Some pumps use a rotor or diaphragm to move the fluid, while others use a piston or valve. In addition, the design of the pump may vary according to the characteristics of the fluid to be used and the requirements of the application.

The pump is widely used in many industrial and domestic applications. For example, pumps are used in many areas such as the transportation of water resources, transportation of oil and natural gas, production and distribution of chemicals, waste water management, ventilation systems and heating-cooling systems.

Pump Types

The working principle of positive displacement pumps is based on the principle of displacement of liquid or gas. The positive displacement pump functions by pushing the liquid or gas with pressure, narrowing or widening the spaces inside the pump.

There are several types of positive displacement pumps, but the most common are gear pump, piston pump, rotary pump, and lobe pump. These pumps work in different ways and provide different benefits for different applications. For example, a gear pump is more suitable for pumping low viscosity liquids, while a piston pump is more suitable for applications requiring high pressure.

The positive displacement pump is a type of pump frequently used in industrial applications and is used in the petroleum, chemical, food and pharmaceutical industries.

The working principle of the diaphragm pump is that there are two chambers above and below a pump body. One of these chambers is the suction chamber, which is below the diaphragm and absorbs the liquid. The other chamber is the pressure chamber, which remains above the diaphragm and evacuates the liquid with pressure.

Other advantages of the diaphragm pump include the absence of leaks, the ability to pump highly viscous liquids, the ability to pump chemical and corrosive liquids, the ability to run dry and low maintenance costs. Therefore, diaphragm pumps are used in many industries, such as the food and pharmaceutical industries, the chemical industry, the petroleum industry, the agricultural and environmental industries.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions