Discover the benefits of Plate Heat Exchangers for efficient heat transfer in industrial processes. Explore our range of high-quality products today.

Showing all 6 results

Gasketed – Hygienic Plate Heat Exchangers

Gasketed – Industrial Plate Heat Exchangers

The global applications for industrial heat exchangers calls for a wide and deep product range, putting great demand on the equipment. SPX FLOW's portfolio of APV ParaFlow is designed to satisfy your needs, whether this is for very small flows, or the extra-large kind, up to 4500 m3/h. With our selection of materials, connections and accessories, we can supply equipment for practically every heat transfer need. The ParaWeld and Paramine technologies expand the boundaries for gasketed plate heat exchangers. Added our long experience in after sales services, SPX FLOW is your all-round partner for heat transfer.

Brazed Plate Heat Exchangers

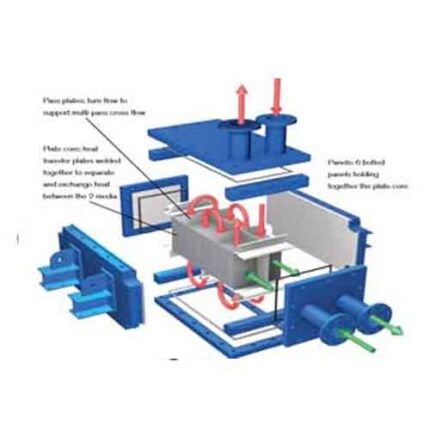

Hybrid Heat Exchanger – All Welded Design

Semi Welded Heat Exchanger – ParaWeld

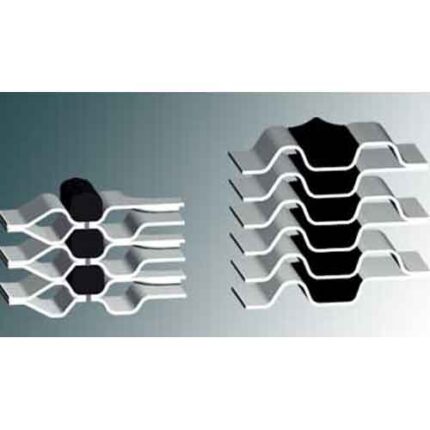

APV Plates

Plate heat exchangers are designed to transfer heat or mass using a series of plates through which fluids pass through spaces between thin metal plates. Plates are generally made of scratch, corrosion and high pressure resistant materials, mostly stainless steel, titanium, nickel or aluminum alloys are used.

Usage Areas of Plate Heat Exchangers

Plate heat exchangers are devices used for heat transfer and are widely used in many industrial applications. Uses for plate heat exchangers may include:

Plate heat exchangers are devices used for heat transfer and are widely used in many industrial applications. Uses for plate heat exchangers may include:

- Heating and Cooling Systems: Plate heat exchangers are used in heating and cooling systems in buildings. While hot water or steam is transferred to heating systems or radiators through plate heat exchangers, in cooling systems the coolant (usually water or antifreeze) is circulated through plate heat exchangers.

- Heat recovery for industrial boilers and steam generators.

- Liquid-liquid heat transfer for central heating systems and heating pumps.

- Heat recovery for air conditioning and ventilation systems.

- Heat transfer of liquids in heating and cooling processes.

- Heat recovery for thermal power plants and industrial energy production.

- Liquid-liquid heat transfer for swimming pool heating systems.

- Food Industry: Temperature control is important in the food industry and plate heat exchangers are used in processes that require temperature control (for example, pasteurization or sterilization). They can also be used to cool or heat food products with hot or cold water.

- Milk processing plants: Plate heat exchangers are used for pasteurization and sterilization of milk.

- Yoghurt and cheese production: They are used for temperature control in fermentation processes of dairy products.

- Fresh fruit juice production: Plate heat exchangers are used for heat treatment of fresh fruit juice and long-term storage.

- Canned foods: They are used in heat treatment processes of canned foods, pasteurization or sterilization of products at appropriate temperatures.

- Beer and alcoholic beverage production: Plate heat exchangers are used for temperature control and cooling in fermentation processes.

- Wine production: Plate heat exchangers are preferred for temperature control in fermentation process of grape juice.

- Coffee and tea processing: They are used to provide temperature control in processes where hot water or steam comes into contact with coffee beans or tea leaves.

- Chemical Industry: In the chemical industry, plate heat exchangers are used to provide controlled temperature conditions in chemical reactions. They can also be used for cooling or heating chemical products.

- Cooling and heating in chemical reactions: Temperature control is very important for keeping chemical reactions under control. Plate heat exchangers are used to remove the heat generated during the reaction or to heat the reaction.

- Recovery of solvents: Plate heat exchangers are often preferred for the recovery of solvents used in chemical production processes. They provide recovery of solvents by using the heat generated by the evaporation of solvents.

- Distillation processes: During the distillation of chemical substances, plate heat exchangers are used to separate components at different temperature levels.

- Cooling and crystallization: Plate heat exchangers are used for temperature control in crystallization processes and for cooling the products.

- Cooling of chemical reactors: In large-scale chemical reactors, plate heat exchangers are used to control the heat generated during the reaction and to cool the reactors.

- Production of industrial chemicals: In the production of industrial chemicals, plate heat exchangers play an important role in many stages where products need to be cooled or heated.

- Oil and Gas Industry: Plate heat exchangers are used in the oil and gas industry for temperature control, heat recovery and inter-process heat transfer. In this industry, special plate heat exchangers that can operate under high pressure and high temperature conditions are preferred.

- Oil refineries: In refinery processes, plate heat exchangers are used in distillation and fractionation processes to separate different components of oil.

- Crude oil processing: During the processing of crude oil, plate heat exchangers are used for temperature control in different processes.

- Natural gas processing and purification: During the purification and processing of natural gas, plate heat exchangers are used for temperature control of the gas.

- Oil transportation lines: During the transportation of oil and gas, plate heat exchangers are used to maintain or correct the temperature of liquids or gases.

- Submarine oil platforms: On subsea oil platforms, plate heat exchangers are used to cool or heat the produced oil.

- Storage and transportation of petroleum products: During the storage and transportation of petroleum products from the refinery, plate heat exchangers are used to regulate the temperature of the products.

- Production of petroleum chemicals: In the production of petroleum-derived chemicals, plate heat exchangers are used for temperature control in chemical reactions.

- Energy Production: Plate heat exchangers are used for steam production, cooling water circulation and heat recovery in power plants (coal, natural gas, nuclear, etc.).

- Thermal power plants: In thermal power plants operating with coal, natural gas or nuclear fuels, plate heat exchangers are used to recover and use waste hot water from steam turbines.

- Combined cycle power plants: In combined cycle power plants where gas turbines and steam turbines are used together, plate heat exchangers are preferred for heat transfer of fluids at different temperature levels.

- Geothermal energy systems: In geothermal energy production, plate heat exchangers are used to use and cool hot water coming out of the ground.

- Solar energy systems: In solar thermal energy systems, collectors that produce heat with solar energy and plate heat exchangers can be used to store this heat or transfer it to other environments.

- Steam generators: In industrial steam generators, plate heat exchangers are used to heat the water used for steam production.

- Nuclear power plants: Plate heat exchangers are used in cooling systems in nuclear reactors and for heat exchange of water used for cooling the reactors.

- Bioenergy systems: In systems producing energy from biomass or biogas, plate heat exchangers are used to heat and gasify organic materials.

- Pharmaceutical Industry: In the pharmaceutical industry, plate heat exchangers are used in various applications such as heating, cooling and sterilization in pharmaceutical production processes.

- Fermentation and biotechnology: Plate heat exchangers are used for temperature control in the growth of microorganisms or cell cultures used in drug production.

- Process control in drug production: Plate heat exchangers are used for temperature control and control of various chemical reactions in drug production.

- Evaporation and condensation: Plate heat exchangers are used for evaporation or condensation of solvents during the processing of drugs with solvents.

- Cooling and heating: Plate heat exchangers are used for cooling or heating of materials used in drug production.

- Cleaning and sterilization: Plate heat exchangers are used for heat transfer of hot water or steam used for cleaning and sterilization of equipment and facilities.

- Production of pharmaceutical water: Plate heat exchangers are used for the production and temperature control of high-quality water (pharmaceutical water) used in drug production.

This covers some of the main application areas where plate heat exchangers are used, but this list is not comprehensive. Plate heat exchangers are often used in many different industrial processes to provide energy efficiency, optimize processes and reduce costs.

The advantages of plate heat exchangers include:

- High heat transfer coefficient: The small gaps between the plates allow the fluids to be close to the plate surface, resulting in a high heat transfer coefficient.

- Efficient: The plates provide a larger surface area, providing a more efficient heat transfer.

- Easy maintenance: The plates can be easily removed and cleaned, which simplifies maintenance and cleaning.

- Space saving: Plate heat exchangers save space as they are more compact than other heat exchangers.

Plate heat exchangers are widely used in many industries such as food, chemical, petrochemical, heating, ventilation and air conditioning (HVAC) systems.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions