Diaphragm Pumps

Diaphragm Pumps are widely used in the food industry. They are frequently preferred in sensitive product transfers such as buttermilk, milk, cream, mustard, mayonnaise, ketchup, due to their properties such as not destroying the chemical properties of the liquid they transfer and not thinning them. They are used in the ceramic industry for the transfer of mud and filling into molds. They also serve in glaze coating processes and for spraying purposes . They provide great convenience to the users in cleaning the oil and sludge formed in the tanks of petroleum products. They are widely used in the circulation of all kinds of chemicals, adhesives, solvents, paints and inks. In addition, since they are safe against burning and explosion, they provide an ideal solution for the transfer of easily flammable products such as perfume and cologne.

When choosing a pump; Flow rate, pressure, viscosity, temperature, solid particle size, specific gravity, pH ratio, and capacity of the compressor must be known. As the product viscosity increases, the pump performance will decrease, so it is essential to know the viscosity value while determining the pump model.

Diaphragm Pump Installation Applications

Diaphragm Pumps

In order to get the best efficiency in diaphragm pumps, a Flow Regulator (Pulsation Damper) should be used in the discharge line. It is recommended to be flexible in the connections of the pump inlet, outlet and air system and to dampen the vibrations in the system.

- A shut-off valve and a drain valve should be applied to the Pump Discharge line.

- A maintenance valve should be applied to the pump inlet line.

- Flexible/hose connection should be used for the valves on the suction and discharge lines.

- Pump Suction and discharge lines should be flexible/hose connection

Pump surfaces are produced as electropolished for the needs of hygienic sectors.

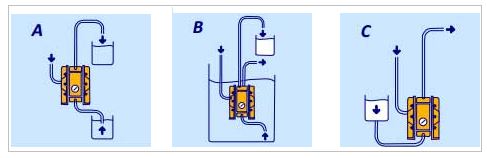

SELF-SUCTION APPLICATION (A):

The pump can suction from 5 meters in dry materials and from 9 meters in liquid products. The suction feature may be variable depending on the Diaphragm Pumps material and the type of product to be shipped. All technical values are calculated according to the transfer of water at 20 °C.

WORKING UNDERWATER (B):

Diaphragm pump can work in fluid.

The issue that should be considered is that the exhaust air outlet should be provided. In addition, the external surface materials of the pump must be resistant to the fluids it comes into contact with.

WORKING UNDER PRESSURE (C):

It is the generally used mode of operation. The product that comes under the tank or with free flow is transferred. The maximum inlet pressure of the fluid coming to the pump should not be more than 0.2-0.3 bar.

Diaphragm Pumps Installation Applications

Diaphragm Pump Installation Applications