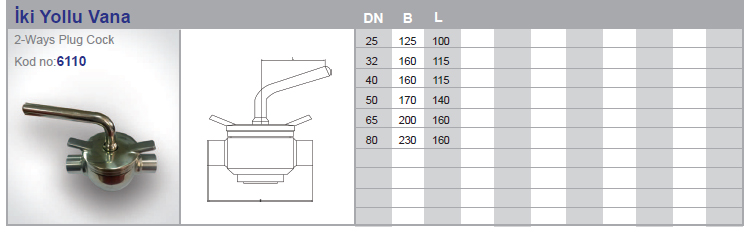

2-Ways Plug Cock

Hygienic 2-Ways Plug Cock are valves that allow flow to be controlled in two directions, especially used in the food, pharmaceutical, cosmetics and other industries. Perform sanitary and safe processes in your various hygienic applications with Sesinoks hygienic 2-Ways Valve. Your solution partner in streaming equipment.

2-Ways Plug Cock (2-Ways Valve):

A 2-Ways Plug Cock is a type of valve used to control flow in a pipeline. Two-way valves allow flow to be controlled in two directions and generally operate with open or closed positions.

2-ways plug cock valves are often used to control the flow of liquid or gas in pipelines. For example, in a water pipeline, a two-way valve may be used to control the flow of water. When the valve is open, it allows water flow, and when the valve is closed, it stops the flow of water.

These valves are widely used in industrial facilities, water purification systems, heating and cooling systems, chemical processes and many other applications. Two-way valves can be of different types and have different features depending on the specific application in which they will be used.

Hygienic two-way valve:

Hygienic two-way valves are a kind of valve type mainly used in food, pharmaceutical, cosmetics and other industries. These valves are designed to meet hygienic standards while being used to control the flow of products. It is generally designed to comply with sealing, cleaning and sterilization requirements.

Hygienic Double-acting Valve is a closing or piston-shaped rotary valve. The valve plug can be cylindrical or tapered. In a cylindrical valve plug, the passage is usually rectangular; In a tapered valve plug, the passage is trapezoidal. It is best suited for use as a cutting and closing agent and shunt, it can also be used for throttling, depending on the applicable properties and the wear resistance of the sealing surface.

Hygienic Two-Way Valve Options:

- Valve body and disc material can be AISI 304 or AISI 316L, 304L and 316 materials are optionally available.

- The seat and seal can be EPDM, VMQ (Silicone), or Viton (FPM), all compliant with FDA 21CFR177.2600.

- End connection can be butt welded, sanitary tri-clamp, threaded, welded or other shapes upon request.

- Handles: 4-position pull handle; Multi-position handle with plastic cover or pure stainless steel.

- Standards: DIN, SMS, ISO/IDF, BS/RJT and ASME/BPE

Features of hygienic two-way valves are:

- Surface smoothness: The inner surface of the valve must be smooth and easy to clean to meet hygiene requirements. This helps prevent product build-up and maintain hygienic standards.

- Sealing: It must have a leak-proof design to prevent products from leaking out or becoming contaminated from the outside.

- Sterilization: Hygienic two-way valves must be resistant to sterilization processes. This enables the use of hot water, steam or chemical sterilization methods.

- Easy cleaning: The valve should be easy to clean and maintain. This ensures that hygiene is maintained during the production process.

Such valves are usually made of stainless steel or other hygienic materials. Hygienic two-way valves are an important component for the safe and hygienic transportation and processing of products and are frequently used in industrial facilities.

Usage areas

Hygienic two-way valves are used in various applications in many industries where hygiene standards are at the forefront. Uses for these valves may include:

- Food industry: Hygienic two-way valves are frequently used in food production and processing facilities. These valves are used to control the flow of liquid or dense food products. For example, hygienic valves can be used in milk processing plants, juice factories, beer and beverage production facilities.

- Pharmaceutical industry: Hygienic valves are used in pharmaceutical production, drug formulation and sterilization processes. Such valves are required for precise metering and mixing of drug ingredients.

- Cosmetic industry: Hygienic two-way valves are used in cosmetic production facilities in the production of products such as cream production, lotion and shampoo. These valves ensure precise mixing and transportation of the ingredients of cosmetic products.

- Drinking water and water treatment plants: Hygienic valves are used in drinking water and water treatment plants for the filtration, disinfection and distribution of water. These valves ensure that water is transported and processed hygienically.

- Hospital and healthcare facilities: Hygienic valves can be used in hospitals and healthcare facilities, sterilization equipment, dialysis systems and medical devices. These valves ensure sterile and hygienic processing of medical products.

Hygienic two-way valves have a wide range of usage areas and are preferred wherever hygiene requirements are at the forefront.

Related products

3-Ways Plug Cock

Diaphragm Valve

Flow Control Valve

Hygienic Ball Valve

A Hygienic ball valve is a type of valve that controls flow along the line in a perforated and rotating sphere. These are the valves that work with the principle of moving the arm on the ball valves by 90°. Flow occurs when the perforated part on the Sphere in the ball valve is brought to the position to be in the same direction as the flow direction. Flow is restricted by moving the lever 90° from this position.