Dellmeco Air Operated Pumps (Diaphragm Pump)

Dellmeco Air Operated Pumps; (Diaphragm Pump) These are self-priming, air-operated pumps produced as stainless steel, teflon, aluminum body. It can transfer products without tiring.

Dellmeco Diaphragm Pump Applications

They are self-priming, air-operated pumps produced as stainless steel, teflon, aluminum body. It can transfer products without tiring. It is used in food products such as milk, ayran and powder transfers. The desired flow can be adjusted with the air setting.

Pump Features

- Diaphragm Pumps are compact and take up little space. It is designed for transfer of abrasive and dissolving products. The product can be used for the transfer of many fluids from the most liquid form to the highly viscous products with solids in it.

- Diaphragm Pumps does not leak because there is no packing in the pump.

- It can be safely used in transferring explosive and flammable products when working with air.

- 9 meters deep suction capability and dry running. The pump output can be easily changed depending on the air inlet. Even when the discharge line is closed, the pump runs smoothly.

- There is no need for Bypass line and Safety valve for investment.

- It has composite and long life diaphragms. There is no need for lubrication, and it can be easily installed on the floor or on the line.

- CE, Atex and TÜV certificates.

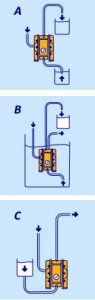

SELF PRIMING APPLICATION (A):

Pumps range in suction lift capability for 5 meters dry. 9 meters can be reached in a primed condition. Suction lift will vary according to materials of construction and application parameters. All data is based on pumping water at 20 C.

Pumps range in suction lift capability for 5 meters dry. 9 meters can be reached in a primed condition. Suction lift will vary according to materials of construction and application parameters. All data is based on pumping water at 20 C.

SUBMERGED OPERATION (B):

All pumps can operate in full submersion. Construction materials must be compatible with the surrounding liquid and the exhaust must be placed above the liquid level.

POSITIVE SUCTION HEAD (C):

Common as a method of drawing off the bottoms of holding tanks or clarifiers. Optimum inlet pressure should be kept at 0.2-0.3 bar.

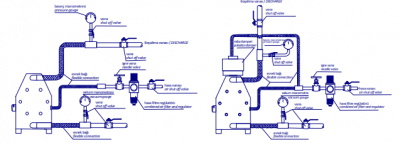

Recommended Installation Guidelines

For best results DELLMECO recommends installing the pulsation damper on the discharge side of the pump. To reduce piping and pump connection stresses, we recommend flexible connections on both inlet and outlet piping and air inlet connections.

- Connect a flow valve and a drain valve to the fluid discharge port of the pump.

- Connect a valve for maintenance to the fluid suction intake port of the pump.

- Connect a hose to the valve on the suction-portside and the valve of the discharge-portside of the pump.

- Connect a hose on the suction-side intake and the discharge-portside to the respective vessels.

Pump surfaces are manufactured as electropolisable for the hygienic sectors requirement.

Pump surfaces are manufactured as electropolisable for the hygienic sectors requirement.

Sanitary Design

Sanitary series is particularly designed to meet the requirements of the food, beverage, pharmaceutical and cosmetic industries. Lubrication-free air distribution system, maintenance-free ball check valve system and total visual inspection of the wetted parts are some of the major features for this pump series.

Our design allows for total visual inspection of the wetted parts. There are no hidden areas where bacteria can grow. The manifold clamps and the housing screws are simply removed for complete disassembly and cleaning. The pump

is also designed for cleaning and sterilization in place – C.I.P and S.I.P After such operations, the pump is easily turned in its support for drainage

Diaphragm Pump Usage Areas

Diaphragm Pump

Air diaphragm pumps are used in a wide variety of industries and applications.

- Chemical Industry: Used for the transfer and dosing of chemicals. It is a suitable option for pumping liquids in chemical processes.

- Water Purification and Wastewater Treatment: Air diaphragm pumps are commonly used to pump liquids in water treatment plants and wastewater treatment plants.

Food and Beverage Industry: Used in food and beverage production facilities, especially for pumping viscous liquids and sensitive substances. - Pharmaceutical Industry: It is preferred for precise pumping of liquid and pharmaceutical raw materials in pharmaceutical production.

- Agriculture and Horticulture: Used to distribute fertilizers, pesticides and other chemicals used in irrigation systems.

- Automotive Industry: Used in the automotive industry for pumping and transporting paint, oil and other liquids.

Mining and Construction: It is used for pumping various chemicals and well water in the mining and construction sectors. - Energy Production: Can be used to transport and pump chemicals used in solar energy, wind energy and other energy production systems.

In addition to these sectors, air diaphragm pumps are often preferred for domestic uses, such as garden irrigation systems or home water pumping operations.