Industrial Check Valves

Industrial Check Valves, check valve or one-way valve is a mechanical control valve that normally allows one-way passage of fluids such as liquid or gas. It is also used for gas fluid in some places. Operational safety is high and they can replace complicated fixtures depending on the situation.

Industrial Check Valve

Check valves are one-way safety valves that allow the liquids passing through the piping to move in one direction, prevent their return, thus ensuring a healthier and more efficient operation of the system. Check valves are simple devices. They perform a very important function by preventing reverse flow.

The reverse flow that may occur in the pipeline is often caused by valves, pumps, etc. connected to the line. may cause damage or malfunction of other devices. It can cause loss of system integrity even if there is no malfunction. The operation of the check valve with a single inlet and outlet is based on the pressure difference. The valve opens when the pressure from the inlet direction is greater than the pressure downstream. If the pressure in the inlet direction is lower than the pressure in the outlet direction, it is closed and the return of the fluid is prevented. Check valves do not require an actuator or manpower as in the on-off principle of other valves. Closing and opening is completely automatic.

Industrial check valve types

There are multiple types of check valves according to the system to be used. Selection should be made according to factors such as the type of fluid, operating mode, installation direction, maximum pressure, connection point, temperature, closing speed. The main varieties are:

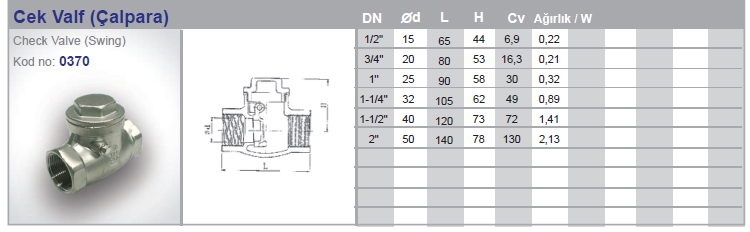

- Check Valve (Swing )

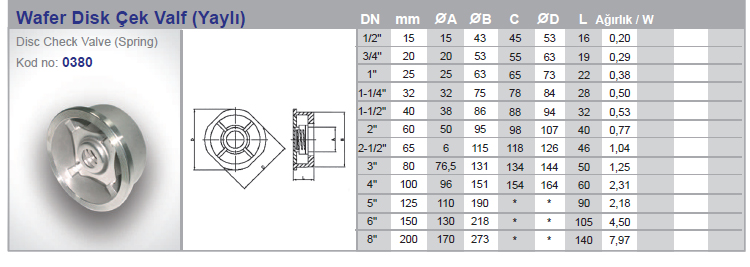

- Wafer Check Valve

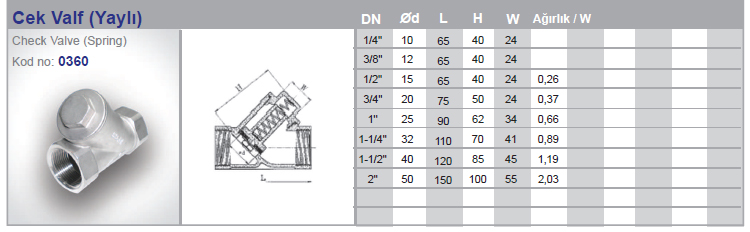

- Spring Check Valve

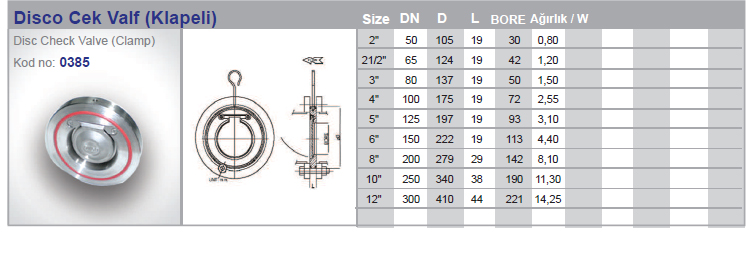

- Disk Check Valve

- Dual Check Valve

Industrial Check Valve usage areas

Industrial check valves are a versatile valve type with a wide range of applications. Some of their uses are:

- Industrial Process Control: Industrial check valves are used to manage liquid or gas flow in process control systems. They are widely used to control liquid or gas flow in chemical, petrochemical, food, pharmaceutical and other industrial facilities.

- Water and Wastewater Applications: Check valves are used in water treatment plants and sewage systems to direct water correctly and control its flow.

- Power Plants: Check valves are used in power generation facilities, especially for the control of steam and water flow. These facilities include thermal power plants, nuclear power plants and hydroelectric power plants.

- Oil and Gas Industry: Check valves are used to control the flow of liquids and gases in oil refineries, petrochemical plants, and natural gas facilities.

- Maritime Industry: On ships, in the maritime industry, check valves are generally used for the correct direction and control of fluids.

- Automotive Industry: In the automotive industry, check valves are used in air intake systems to control air flow in engines.

Air Conditioning and Ventilation Systems: Check valves are used to control air flow in air conditioning and ventilation systems in buildings.

Food and Beverage Industry: Check valves are used in food processing plants, for example in the storage, transportation and processing of liquids.

These are just a few of the uses for industrial check valves. In general, check valves are widely used in almost every industrial application where the flow of liquid or gas must be controlled.