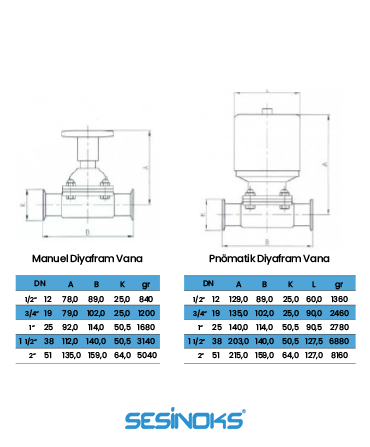

Diaphragm Valve

Diaphragm valves are a type of valve used in places where remote control is desired to be opened and closed, or where the contact of the fluid in the process with the valve mechanisms is not desired.

Diaphragm Valves

Diaphragm valves are an important type used to control the flow of liquids or gases in many industries. These valves are known for their simple yet effective design and are often preferred in applications requiring precise control.

Diaphragm valves (also known as membrane valves) are valves that have an on-off system with the effect of the pressure of the water passing through them on the diaphragm.

Diaphragm valves are a type of valve used in places where remote control is desired to be opened and closed, or where the contact of the fluid in the process with the valve mechanisms is not desired.

Working Principle of Diaphragm Valves

The basic operating principle of diaphragm valves is the use of a flexible diaphragm. This diaphragm flexes under the pressure of the fluid and opens or closes the holes in the valve body. It usually consists of a diaphragm built into a valve body and a control mechanism mounted on top. Pressure changes regulate flow by controlling the movement of the diaphragm.

In diaphragm valves, the so-called “Pilot system”; able to work with little power; There is a mechanism that directs a small amount of water flowing through it and directs some water to the upper part of the diaphragm or to the outlet. This system, which can operate even with a small current produced by the battery, is possible to open and close the valve by controlling the pilot system with the help of an electronic circuit. For this reason, diaphragm valves seem to be almost the only solution in places where it is desired to start or cut off the flow of water with a remote control.

Another usage area is places where it is desired to provide or prevent flow by preventing chemicals with high destructive properties from damaging the valve (such as chemistry laboratories). The diaphragm between the valve mechanism and the fluid (It is manufactured from different materials that are not affected by chemicals, such as natural rubber, PTFE, Viton, Hypalon, with original formulas.). Since it prevents the contact of the mechanism with the fluid, the valve can open and close for a long time.

Types of Diaphragm Valves

Diaphragm valves can be classified in several ways:

Single Diaphragm Valve: It has a single diaphragm and is generally used in simple control applications.

Single Diaphragm Valve: It has a single diaphragm and is generally used in simple control applications.- Double Diaphragm Valve: Used in more complex applications, these types of valves provide greater reliability and safety.

- Pilot Controlled Diaphragm Valve: Uses a pilot valve to control flow. This is used to provide more precise control.

Usage Areas of Diaphragm Valves

Diaphragm valves are widely used in many industries:

- Chemical Industry: Diaphragm valves are frequently preferred for the control of chemicals. They are used in chemical processes that require precise control.

- Water and Wastewater Treatment: Diaphragm valves are frequently used in water and wastewater treatment plants, as fluids need to be precisely controlled.

- Pharmaceutical Industry: In pharmaceutical production, diaphragm valves play an important role as ingredients need to be precisely dosed.

Food Industry: Diaphragm valves are used in food processing plants to hygienically control liquid and gas flows.

Food Industry: Diaphragm valves are used in food processing plants to hygienically control liquid and gas flows.- Automation and Control Systems: In industrial automation and control systems, diaphragm valves are often used to automate and control processes.

Advantages of Diaphragm Valves:

Some advantages of diaphragm valves are:

- They have a simple and reliable design.

- They provide precise control.

- They have wide usage in various industries.

Disadvantages of Diaphragm Valves:

- They can be difficult to use in high pressure applications.

- If the diaphragm material is not selected appropriately, chemical incompatibilities may occur.

As a result, diaphragm valves play an important role in the industry. Their simple design and precise control capabilities make them preferred in many applications. However, it is important to consider application requirements and choose the right materials.

Related products

3-Ways Plug Cock

Air Operated Valves (Pneumatic valve)

Flow Control Valve

Hygienic Ball Valve

A Hygienic ball valve is a type of valve that controls flow along the line in a perforated and rotating sphere. These are the valves that work with the principle of moving the arm on the ball valves by 90°. Flow occurs when the perforated part on the Sphere in the ball valve is brought to the position to be in the same direction as the flow direction. Flow is restricted by moving the lever 90° from this position.