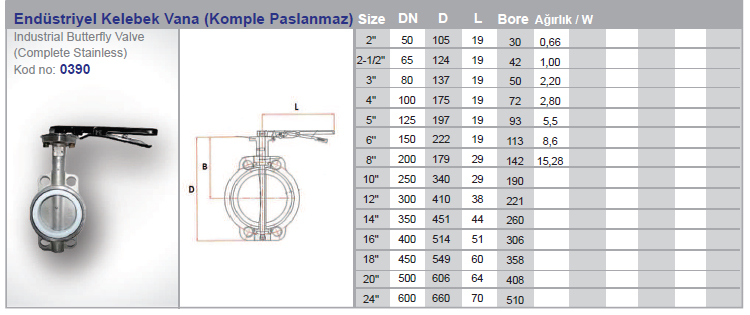

Industrial Butterfly Valve

Industrial Butterfly valves; It is a type of valve developed to produce more economical solutions in the control of fluids, which is simple, compact, takes up little space, provides 100% tightness and is used for controlling liquids or gases.

industrial butterfly valve

Butterfly valves are used in a wide variety of industries, particularly in water supply, collection and distribution, as well as in pumping stations, and they have a wide variety of use cases, particularly in flow isolation.

Butterfly valves are a family of quarter-turn rotary valves used to shut off flow in pipelines.

Industrial butterfly valve is a type of valve used to control the flow of liquid and gas in industrial facilities.

Industrial stainless butterfly valve

Stainless butterfly valves are generally made of stainless steel and are preferred because they are particularly resistant to corrosion.

Stainless butterfly valves are generally made of stainless steel and are preferred because they are particularly resistant to corrosion.

These valves allow a disc or plate to rotate, opening or closing the flow. They generally have a rapid opening and closing structure, allowing the controlled flow to be quickly interrupted or started. Industrial butterfly valves are used especially in large diameter pipelines and high flow systems.

Types of butterfly valves are:

- Central flange butterfly valve: This type of industrial butterfly valves is installed inside the pipeline and connected by a central flange.

- Positioned flanged butterfly valve: These valves have a structure with flanges on both sides, so they are easier to install.

- Semi-flange butterfly valve: This type of valve has a structure that has a flange on one side and can be welded to the pipeline on the other side.

- Triple offset butterfly valve: These valves have a triple offset structure on the disc to ensure higher performance and tightness.

The usage areas of butterfly valves are quite wide. For example, they are widely used in petrochemical plants, water treatment plants, power plants, chemical industry, shipping industry, gas distribution and general industrial processes. Stainless butterfly valves are especially preferred in the food industry, pharmaceutical industry and chemical processes because they have hygienic and corrosion-resistant properties.