KVB Electric Barrel Pumps

KVB-25 Electric barrel pumps are hygienic vertical multistage cavity pumps. Drum pumps are specially designed to transfer high or low viscosity media from tanks and drums via a pump pipe inserted into the drum.

Some of the most important applications of the type of KVB-25 barrel pumps are the transfer of fruit concentrates for beverage production, tomato concentrates for ketchup production, cream, honey and other high viscosity media.

KVB Barrel Pumps Application

The KVB-25 Electric Barrel Pumps are hygienic vertical progressive cavity pumps. They are specially designed to transfer media of either high or low viscosity from tanks and barrels by means of a pump tube introduced into the drum.

Some of the most important applications of this pump type is transferring of fruit concentrates for the beverage production, tomato concentrate for the ketchup production, transferring of creams, honey and other media of high viscosity.

Pumping is characterised by a gentle transfer of media with shear sensitive particles

Electric Barrel Pump Operating principle

The pump tube is introduced into the drum with the media to transfer.

Friction between the stator and the rotor creates vacuum at the inlet of the pump thus

facilitating the entry of the product into the pump.

The turning motion of the rotor makes the cavities between the rotor and the stator move forward and transport the product to the outlet.

Design and characteristics

Design and characteristics

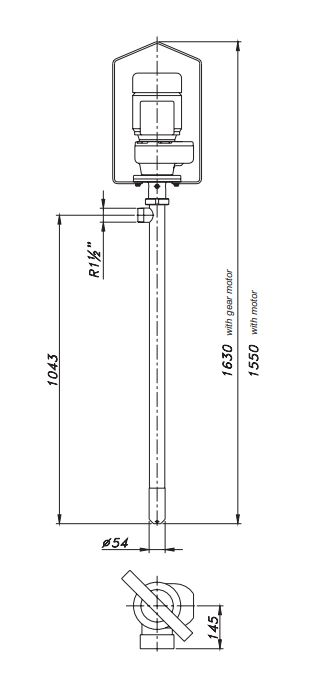

- Vertical pump

- Internal single mechanical seal EN 12756 (DIN 24960 L1K)

- Impulsion connection BSP 1 ½”

- Surface finish Ra<0,8 μm

- Pump tube diameter 54 mm

- Drive: Motor 1,5 kW 1000 rpm

- Pump support

Materials

Parts in contact with the media: AISI-316L

Other stainless steel parts: AISI-304

Stator: black NBR (FDA certified)

Gaskets: NBR

Mechanical seal (standard): SiC/SiC/FPM

Options

Stator: white NBR and EPDM (white or black)

Gaskets: EPDM (FDA certified) and FPM

Mechanical seal: SiC/C

Drive: motors at 900 rpm

Drive: geared motor or variable speed drive

Other connections (Clamp, DIN, SMS, RJT…)

Technical specifications

Max. flow: 1,6 m3/h

Max. operating pressure: 6 bar

Max. working temperature: 90 ºC

Max. viscosity: 40.000 mPa.s