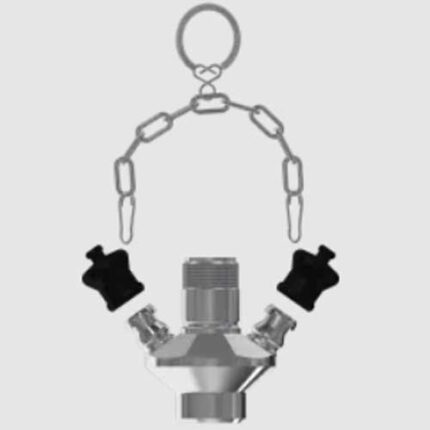

Sampling Valve

The Sampling Valve is designed for quality control during production. The end product and the different stages of production require a rigorous sampling process.

Sampling Valve Application

Sampling valves are designed to solve the need for sampling in liquid processing plants in the food processing and chemical industries, as well as in any other process that requires sanitary equipment. The Sampling Tap can be used safely in the pharmaceutical and beverage industries.

Sample Valve Operating principle

The sample is obtained by removing the head to dislodge the membrane, allowing the liquid to enter the outlet tube.

Samples taken play an important role in researching and verifying product quality. The method of sampling directly from the production without sampling cock, creates the risk of contamination and environmental pollution.

For this reason, if product safety is your top priority, a bacteriologically safe Sampling Tap, which ensures high product quality control at every stage of production and guarantees eliminating risks in sampling applications, should be used. In this way, you ensure maximum safety and a long production life without unexpected errors. In particular, sampling from liquid products may cause contamination of the product if a liquid sampling valve is not used, and sampling from chemical products may cause environmental pollution if a chemical sampling valve is not used.

Liquid Sampling Valve Design and features

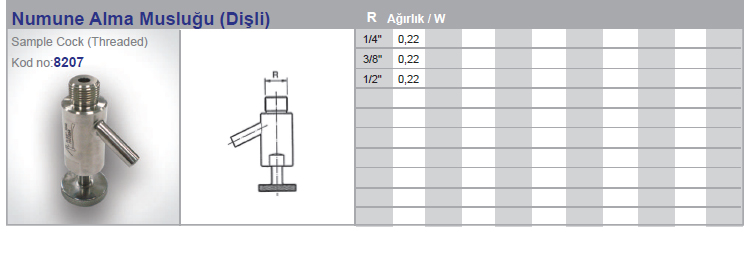

Ø available: ¼” ve ½”

Thread connection: ISO 228-1

Chemical Sampling Valve Materials

Metal parts: AISI 304L

Pivot lock: PTFE

O-ring: NBR

External surface finish: elektro cilalı

Sampling Valve Features

SIP/CIP input is available for sterilization,

SIP/CIP input is available for sterilization,- Flexible and easy maintenance and assembly,

- Thanks to the stainless steel shaft, it prevents infection. No need for an extra bearing gasket,

- It is cleanable, no dead spots in the valve body,

- Suitable for all standard connection types,

- Pneumatic type is available.

- It can be used with other equipment on the line without any problem,

- It can be welded directly to the tank or even,

- Valve shaft in contact with the product is completely stainless steel,

- Optionally; inlet/outlet dimensions and connection types can be provided in 1/2”-1” nominal diameters,

- AISI 316L quality stainless steel shaft,

- Surface roughness can vary up to Ra≤10 m and can be electro polished,

- standard design,

- Long lasting

Seçenekler

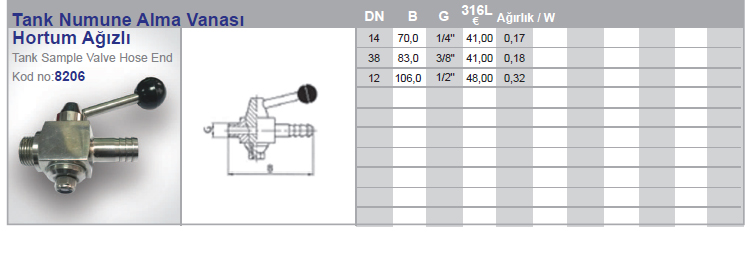

- Upper level valve.

- Upper level valve drain outlet.

- Level valve for drain hose.