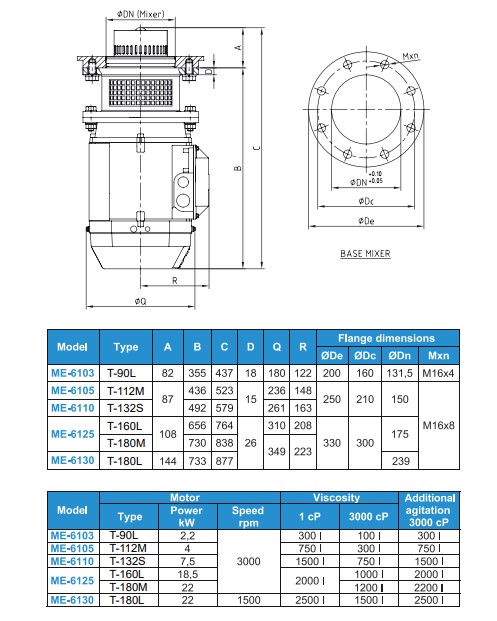

Tank Bottom Mixer

The ME-6100 series of the high shear bottom of the tank mixers present a highly hygienic solution for the processes of dispersion, emulsifying, homogenisation and disintegration of solids in the food-processing, cosmetics, pharmaceutical and fine chemistry industries.

Tank Bottom Mixer Application

The ME-6100 series of the high shear bottom of the tank mixers present a highly hygienic solution for the processes of dispersion, emulsifying, homogenisation and disintegration of solids in the food-processing, cosmetics, pharmaceutical and fine chemistry industries.

These mixers can be used either in open or closed tanks at atmospheric pressure or under pressure/vacuum.

The bottom of the tank mixers are designed for the applications of the highly viscous media and intended for work with anchor type agitators

Tank Bottom Mixer – ME-6100 Operating Principle

The high speed and adjusted tolerances between the rotor and the stator result in high suction potential, the product is suctioned and driven to the centre of the head.

The product is suctioned from the upper part of the head and the rotor thrusts it radially.

Passing through the opening of the stator the product is mechanically sheared, the particles are sheared by the rotor at 20 m/s. And finally this flow is hydraulically sheared leaving the stator through the slots at a high speed.

Tank Bottom Mixer – ME-6100 Design and features

- High shear, particle size reduction to less than 100 microns.

- Access to the mechanical seal from the inside of the tank.

- Single sanitary mechanical seal.

- Possibility to replace the stator without disassembling the mixer.

- The circulation is promoted as the stator is geometrically higher than the rotor .

- Motors: IEC B5, IP 55, F-class insulation.

- Easy cleaning and sterilisation (CIP/SIP).

- Various easily interchangeable head models.

- Slotted head.

Mixer For Tank Materials

- Parts in contact with the product : AISI 316L

- Other stainless steel parts : AISI 304

- Mechanical seal : C / SiC / EPDM

- Gaskets : EPDM according to FDA 177.2600

- Surface finish : electropolished, : Ra ≤ 0.8 Μm

Bottom of the Tank Mixers Options

Flushed mechanical seal.

Flushed mechanical seal.- Pressurised mechanical seal by means of a lip seal or double mechanical seal.

- Disintegrating head.

- Fine screen head.

- Bare shaft construction for big size models, transmission by pulleys and belts.

- Assembly of cutters and propeller on the upper part of the rotor.

- Surface finish: Ra ≤ 0,5 Μm for the pharmaceutical applications.

- Other motor protections.