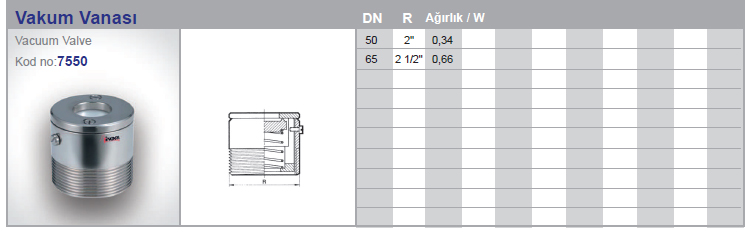

Vacuum Valves

Vacuum valves are valve installed in the supply or exhaust line of a vacuum system. Vacuum control valves are a valve designed to maintain atmospheric pressure within the tank while the tank is being filled or emptied. The system is sealed until overpressurized. It is set to expel excess gas when a set pressure threshold is exceeded.

Vacuum Control Valve

Vacuum Valves are device installed in the supply or exhaust line of a vacuum system. It is often used to isolate vacuum areas such as process rooms or to control incoming and outgoing gas volumes. The Vacuum Valve can be operated manually, pneumatically, electropneumatically, electrically or electromagnetically.

The Vacuum Valve is designed to provide a tight seal until the system pressure or vacuum exceeds the valve’s set pressure. When overpressure builds, the pressure disc lifts just like a safety valve, allowing vapors to pass through.

Vacuum Valve Application

Pressure-vacuum valve is widely used in the food-processing, wine-making, cosmetics and chemical industries as well as in the beverage and oil production.

Vacuum Valves Operating Principle

The pressure-vacuum valve is designed to breathe in while the tank is being emptied to equal the pressure inside and outside the tank and protect the tank from vacuum.

When the tank is being filled, the pressure-vacuum valve allows air to come out, thus avoiding excess pressure inside the tank which would cause the tank to swell.

Usage Areas of Vacuum Control Valves:

Vacuum control valve is a type of valve commonly used in many industrial applications. Below are some common uses of vacuum valves:

Vacuum control valve is a type of valve commonly used in many industrial applications. Below are some common uses of vacuum valves:

- Vacuum systems: Vacuum valves are used in industrial vacuum systems for the control of vacuum pumps and vacuum chambers. These systems are used in production lines, laboratories, the packaging industry and many other areas.

- Food industry: In the food processing industry, vacuum valves are used in vacuum packaging machines and food production lines. Vacuum packaging process is frequently used to extend the shelf life of packaged foods and preserve the freshness of the products.

- Medical devices: Vacuum valves are used in many areas of medical devices. For example, vacuum valves are used in vacuum aspirators, dialysis machines, and laboratory equipment.

- Industrial robotic systems: In automation systems and industrial robotic applications, vacuum valves are used in robot grasping and manipulation processes. Vacuum valves play an important role in processes such as transportation, placement and assembly of products.

- Chemical industry: In the chemical industry, vacuum valves are used in various chemical processes. These processes may include distillation, drying, filtration and vacuum distillation.

- Pharma industry: In pharmaceutical production, vacuum valves are used in various processes. Vacuum valves play an important role in drug formulation, drying processes and packaging processes.

- Energy industry: Vacuum valves are used in energy production and distribution. In power plants, refineries and other energy facilities, vacuum valves are used in process control and equipment maintenance.

These are just a few examples of the uses of vacuum valves. These valves are considered an essential component in helping to reliably control vacuum in many industrial processes.

Related products

2-Ways Plug Cock

3-Ways Plug Cock

Diaphragm Valve

Hygienic Ball Valve

A Hygienic ball valve is a type of valve that controls flow along the line in a perforated and rotating sphere. These are the valves that work with the principle of moving the arm on the ball valves by 90°. Flow occurs when the perforated part on the Sphere in the ball valve is brought to the position to be in the same direction as the flow direction. Flow is restricted by moving the lever 90° from this position.