Vertical Mixer Application

The ME 1100 series of the high shear vertical mixers present a solution for the processes of dispersion, emulsifying, homogenisation and disintegration of solids in a wide range of products in the food-processing, cosmetics, pharmaceutical and fine chemistry industries.

These mixers are intended for work under the atmospheric pressure and with the products of either high or low viscosity. The mixers are recommended to work with anchor type agitators if the application involves highly viscous media.

Vertical Mixer – ME 1100 Operating Principle

The high speed and adjusted tolerances between the rotor and the stator result in high suction potential, the product is suctioned from the bottom of the tank and driven to the centre of the head.

The product is suctioned from the lower part of the head and the rotor thrusts it radially. Passing through the openings of the stator the product is mechanically sheared. the particles are sheared by the rotor at 20 m/s. And finally the product is hydraulically sheared while leaving the stator through the slots at a high speed . At the same time the product returns to the working head ensuring the mixing circle and generating a strong circulation inside the tank. The combination of the vertical suction and radial thrust results in a circulation flow.

If the size and the power of the mixer are correctly selected, the ingredients contained in the tank pass through the working head hundreds of times that promotes a progressive and uniform homogenization. Other important feature is the possibility to minimize the aeration of the product

Vertical Mixer – ME 1100 Design and Features

- High shear, particle size reduction to less than 100 microns.

- V-ring.

- Slotted head (standard).

- Possibility to replace the stator and the bushing without disassembling the mixer.

- Various types of interchangeable heads.

- Motors: IEC B5, IP55, F-class insulation.

Materials

- Parts in contact with the product : AISI316L

- Guide bushing : PTFE

- V-ring : NBR

High Shear Vertical Mixers Options

- DIN2632-PN10 flange or rectangular flange for the assembly on a tank.

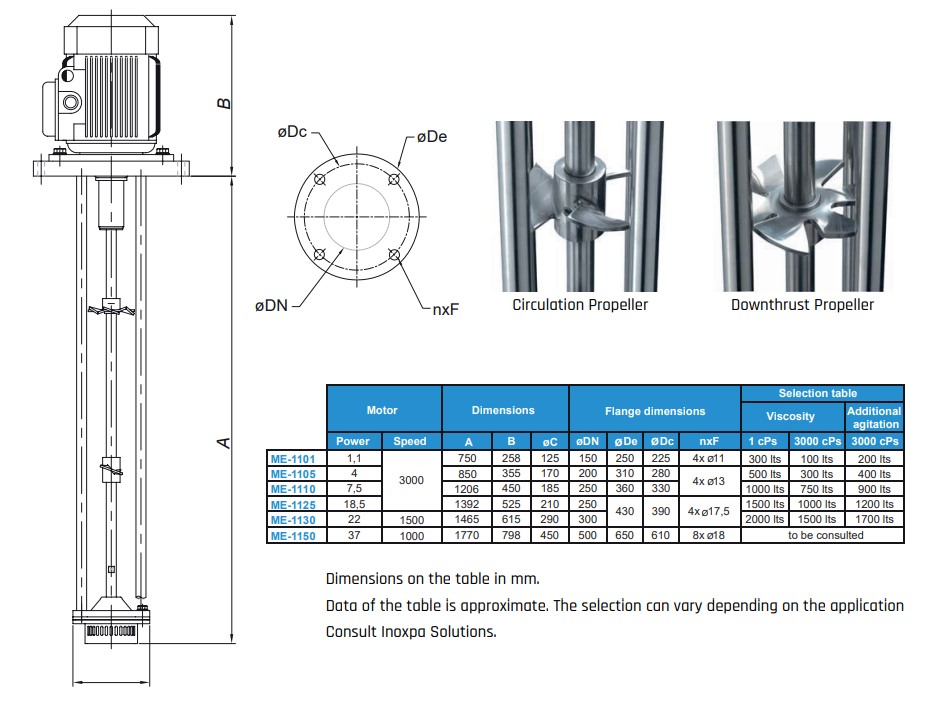

- Circulation propeller.

- Downthrust propeller.

- Peak friction bushing and ceramic lined shaft for abrasive media.

- Disintegrating head.

- Fine screen head.

- Intermediate flange for long mixers.

- SLIM system.

- Upper suction head.

- Motor shroud.

- Other motor protections.

Vertical Mixers

- High Capacity: Industrial vertical speed mixers are generally designed to process large quantities of materials. This allows them to work quickly and effectively in busy kitchen environments.

-

Durability and Reliability: Industrial mixers are made of durable materials to withstand constant use. Powerful engines and solid structure provide long-lasting performance.

-

Various Attachments and Accessories: Industrial mixers often come with interchangeable heads and accessories for different functions. This allows different types of dishes to be prepared and various operations to be carried out.

-

Easy Cleaning and Maintenance: Industrial mixers are generally designed for easy cleaning and maintenance. High-quality stainless steel surfaces and removable parts make cleaning easy.

-

Power and Speed Control: These types of mixers are usually equipped with settings that provide power and speed control. This allows you to set the appropriate speed and power for processing various materials.

-

Different Sizes and Models: Industrial high shear vertical mixers are available in different capacities and features, so you can choose the one that suits your business needs.

These mixers are ideal for commercial kitchens that need to process large amounts of ingredients. However, it is important to do your research before purchasing, taking into account your business needs. Additionally, a reliable company like Sesinoks is important for purchasing support and long-term use.