Using Blender

Using Blender for Liquid Powder Mixtures

Using Blender, Liquid powder mixing systems, which are generally used in milk, fruit juice, ice cream, chocolate, cosmetics and chemical industries, provide different advantages with the use of different equipment in each production branch.

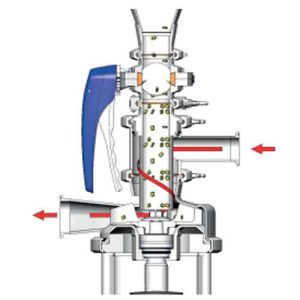

Mixing systems consist of a funnel-shaped chamber to ensure the participation of the powder material in the system and a part mounted at the bottom of this chamber, providing the liquid material inlet. Mixing takes place at the point where powder and liquid first meet, with an open fan..

In order for the mixture to be provided correctly, the following conditions must be met.

- Allowing the powder to flow through the existing funnel, depending on its structure and moisture retention.

- Bringing the existing liquid inlet point with the powder material to the mouth of the mixture by providing a circular flow

- For homogenization as a result of mixing, the system should be supported with circulation or, if necessary, an extra mixer.

|

|

Using Blender: The powder material structure written in the first article is very important for the mixture. If the powder material becomes sticky at the point where it meets the liquid or is affected by the external humidity, it will be very difficult to move this material in the funnel after the system starts to work. For this purpose, if the moisture retention feature of the powder material is not very high, a vibration device is mounted on the existing funnel in the blender, so that the powder flows regularly to the mixing nozzle.

|

|

The connection diameter and angle at the entry point of the existing fluid into the system provide the mixture at the mixer mouth by making a circular motion of the liquid at high speed.

Depending on the characteristics of the system to be used, the system can be supported with an in-line mixer for homogenization after the mixture or a positive displacement pump if the mixture viscosity is too high. Using Blender

Powder level sensor, start-stop, vibration and flow control can be applied especially in automation application for system elements that can be connected to manual and automation.

Generally, funnel system users in the dairy industry use a sieve system at the powder entry point for the blender systems they use to melt milk powder. Thus, foreign matter entry into the system is prevented.