Olive Oil Milk and Beverage Tank Mixing Process

In Olive Oil Milk and Beverage Tank Mixing Process, Side mounted tank mixers (horizontal mixers) are used in process and storage tanks in applications of the food processing industry. They are most preferred in milk, beverage and oil tanks. The main application is to store water, oil, milk, beverage, alcohol etc. in large volume tanks. It is the mixing of low viscosity products such as. The main purpose of this mixing is; It prevents sedimentation and sedimentation in stationary stock tanks and provides a homogeneous structure inside the tank.

Mixers Used in Olive Oil Milk and Beverage Tank Mixing Process

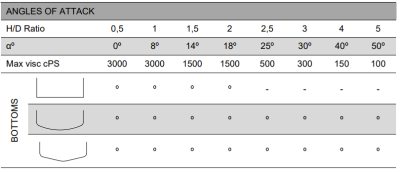

Mixers are manufactured in two types, with direct motor connection (1500 rpm -1000 rpm) or reducer connection (200 rpm). They are used in products with a viscosity between 1 and 1000 cpu. As the product viscosity increases, the number of revolutions must decrease. In tanks with direct engine connection; Shaking that may occur in the tank during the first take-off, etc. It is recommended to use it with a driver to prevent negativities such as As viscosity increases, engine speed decreases and mixer blade diameter increases.

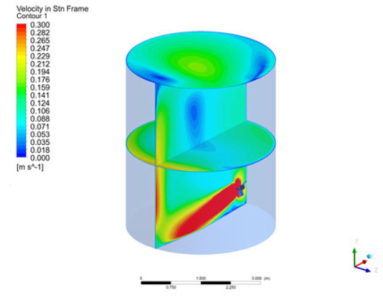

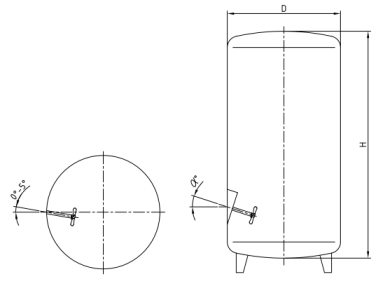

Installation of side mixers is done at an angle. In this way, the product is pushed to the bottom of the tank by the rotation of the impeller and then rises to the surface along the wall opposite the mixer. Depending on the process situation, if there are parts such as a crusher inside the tank, this will positively affect the formation of homogeneous products.

Installation of side mixers is done at an angle. In this way, the product is pushed to the bottom of the tank by the rotation of the impeller and then rises to the surface along the wall opposite the mixer. Depending on the process situation, if there are parts such as a crusher inside the tank, this will positively affect the formation of homogeneous products.

Installation of Mixers Used in Olive Oil Milk and Beverage Tank Mixing Process

Installation of Mixers Used in Olive Oil Milk and Beverage Tank Mixing Process

Mixer installation is carried out according to the table below.

The mixer is installed in a decentralized manner to improve circular flow. This ensures complete homogenization of the product.

The mixer is installed in a decentralized manner to improve circular flow. This ensures complete homogenization of the product.

Karıştırıcı tasarımı, motor dönerken, kanadı sıkma esasına göre yapılmıştır. Bu nedenle ilk çalıştırmada motor dönüş yönünün doğru olması çok önemlidir. Aksi halde kanat, açılıp, tankın içine düşebilir.