Brazed Plate Heat Exchangers

Discover the efficiency and durability of our Brazed Plate Heat Exchangers. Perfect for a wide range of industrial applications. Order yours today.

APV ParaBrazed is a large range of compact brazed plate heat exchangers specially designed for a multitude of heating and cooling applications with high temperature and/or pressure.

APV ParaBrazed is characterized by: :

- Compact design with minimum space requirement

- High heat transfer efficiency

- Flexible in use

- Working temperature 195°C/-50°C

- Working pressure up to 30 bar

Working principle

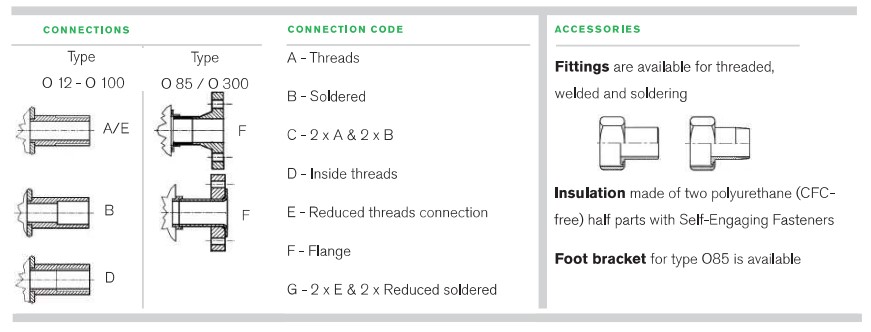

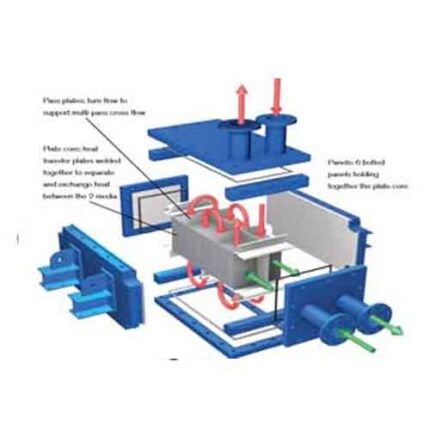

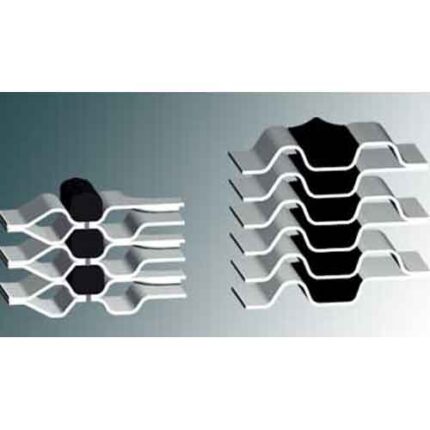

APV ParaBrazed is a simple construction consisting of corrugated metal plates stacked on top of each other. The front and rear cover plate on which connections are located covers the plate pack. The plate pack, cover plates and connections are copper brazed to obtain a compact and highly durable plate heat exchanger. High thermal efficiency is obtained by letting the two media in parallel flows run in countercurrent flow through alternate channels.

Application:

APV ParaBrazed is specially designed for heating and cooling of liquids in industrial, HVAC and refrigeration applications.

Typical HVAC applications include heating of domestic water and central heating water – radiators as well as floor heating – primary heating sources being e.g. district heating, solar heating, and heat pumps. In refrigeration APV ParaBrazed is often used for evaporation and condensations duties with freon-like liquids as primary source. Other applications include oil coolers and oil heaters.

Note: Ammonia and seawater must not be used as media in

Benefits:

The APV ParaBrazed heat exchangers are easy to mount and install, and their compact design requires minimum space.

Due to the large temperature span and high working pressure APV ParaBrazed offers high flexibility in use. Its high thermal efficiency reduces the consumption of the heating media to a minimum making the ParaBrazed range of plate heat exchangers an efficient and cost-effective choice.

Technical data

- Material:

- Plates and connections: AISI 316 (W.-1,4401)

- Soldering: Copper 99,9%

- Working condition:

- Max./min. working temp.: +195/-50°C.

- Max. AT prim./sec.: 150°C

- Approval: Modul A1 Pressure Equipment Directive PED 97/23/EU; TÜV Thüringen (CE 0090)

- Custom design: Non standard sizes and connection variants are possible

Usage Areas of Brazed Plate Heat Exchangers

Brazed plate heat exchangers are an important type of equipment that is effectively used in heat transfer processes and has a wide range of applications. The uses of these exchangers are diverse and are widely used in various industrial, commercial and even domestic applications.

- First, in industrial processes, brazed plate heat exchangers are used to provide temperature transfer of liquids, gases or vapors. Temperature control is critical in many industrial sectors such as chemical processes, petrochemicals, and food and beverage production, and brazed plate heat exchangers meet this need.

- Secondly, brazed plate heat exchangers are also frequently used in heating, ventilation and air conditioning (HVAC) systems. These exchangers are included in heat and cooling systems used to control temperature and air quality inside buildings. Many structures such as large buildings, hotels, hospitals and industrial facilities have HVAC systems, and brazed plate heat exchangers increase the efficiency of these systems.

- Third, brazed plate heat exchangers are widely used in the transportation and transportation industry. Especially in vehicle cooling systems, brazed plate heat exchangers are found in the cooling systems of commercial vehicles and transportation vehicles. Temperature control is critical in food transportation, pharmaceutical transportation and other sensitive products, and these exchangers meet this requirement.

- Fourth, brazed plate heat exchangers are also used in renewable energy systems. Especially in solar and geothermal energy systems, these exchangers play an important role in heat transfer and temperature control. Brazed plate heat exchangers are preferred in solar energy collection systems or in the use of hot water obtained from geothermal sources.

- Finally, brazed plate heat exchangers are also used in industrial cleaning systems and waste heat recovery. While hot water or steam is used in industrial cleaning processes, the heat obtained from production processes is evaluated and reused through waste heat recovery. The role of brazed plate heat exchangers is critical in these processes.

In general, brazed plate heat exchangers are a versatile and important heat transfer equipment used in a wide range of applications, from industrial processes to HVAC systems, from the transportation industry to renewable energy systems.