EFI Industrial Centrifugal Pumps

The Estampinox EFI Industrial centrifugal pump is a stainless steel centrifugal pump designed to transfer low viscosity water and other liquids from one place to another. It is designed to meet the needs of ancillary services in the food processing, chemical, pharmaceutical and winemaking industries.

Application

The Estampinox EFI pump is a stainless steel centrifugal pump ideal for the transfer of water and other low viscosity liquids. It is designed to cater for the needs of auxiliary services in the food-processing, chemical, pharmaceutical and wine-making industries.

Industrial centrifugal pumps are used to transport liquids. They are often used in industrial applications, water supply systems, wastewater treatment plants, chemical plants, petrochemical industry and many other areas.

These pumps operate with a fixed outer sleeve (stator) rotating around a central rotating ring (rotor). The process is a process in which the liquid is drawn towards the center by the rotation of the central rotor, gains speed and is thrown outwards.

Industrial centrifugal pumps are generally preferred for high volume and high pressure liquid transfers. They are driven by powerful motors and are used reliably in a variety of industrial environments.

Estampınox EFI Centrifugal Pumps Design and Features

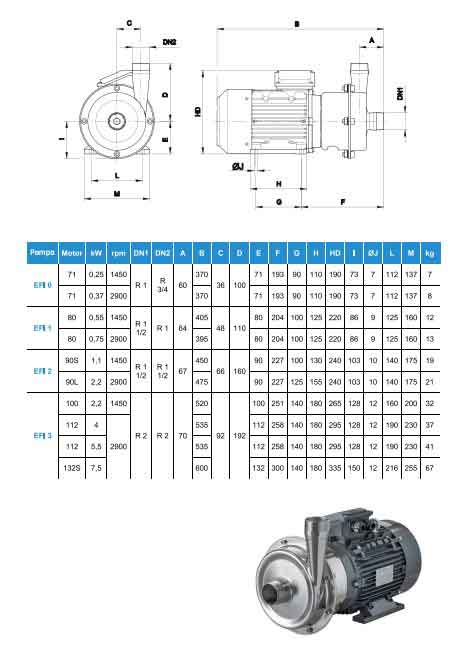

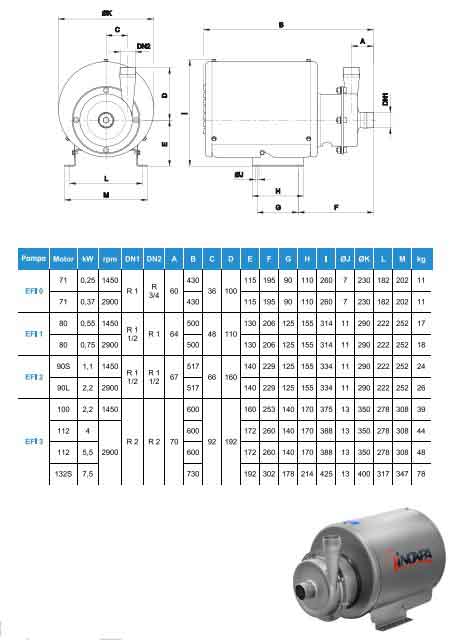

Estampinox EFI is a range of close-coupled centrifugal pumps. It is made of a cold-formed stainless steel casing, open impeller manufactured with stainless steel cold-formed plate or investment casting (according to model), mechanical seal, pump cover, lantern and shaft. Estampinox EFI centrifugal pump is provided with an internal single mechanical seal.

Motor

Triphasic induction motor with B34 flange (B35 for motor frame 132), in compliance with the IEC standards, 2 poles = 3000/3600 rpm, efficiency class according to EC regulation, IP 55 protection and F-class insulation.

3 phases, 50 Hz, 230 V Δ / 400 V Υ, ≤ 4 kW

3 phases, 50 Hz, 400 V Δ / 690 V Υ, ≥ 5,5 kW

Technical Specifications

Materials:

Parts in contact with the product: Stainless steel AISI 316L (1.4404)

Other steel parts: Stainless steel AISI 304 (1.4301)

Gaskets in contact with the product: EPDM

Mechanical seal:

Rotary part: Ceramic (Cer)

Stationary part : Carbon (C)

Gaskets: EPD

Surface finish:: Matt

Connections: Threaded connection (ISO 7)

Operating limits:

Maximum working pressure : 6 bar 87 PSI

Temperature range : -10°C ila +120 °C 14 °F ila 248 °F

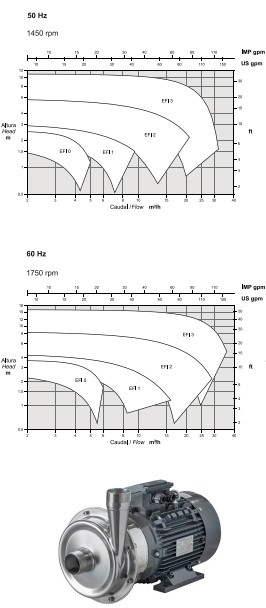

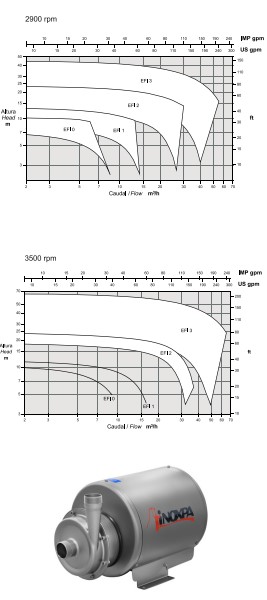

Maximum flow: 65 m³/h 286 US GPM

Maximum differential head: 66 m 217 ft

Maximum speed : 3500 rpm

Options

- AISI 304 stainless steel motor shroud.

- Other materials for mechanical seals and gaskets.

- Different types of connections.

- Motor with other voltages, frequencies, mechanial protections and efficiencies.

- Trolley and/or control panel.

Industrial centrifugal pumps have a wide range of usage in various sectors. These sectors include:

- Water and Wastewater Treatment Industry: Centrifugal pumps are generally used in many applications in water and wastewater treatment plants, such as pumping water, filtration processes, and transporting sludge and wastewater.

- Oil and Gas Industry: In areas such as oil refineries, oil wells, and the gas industry, centrifugal pumps are used to transport and process crude oil and pump refined products.

- Chemical Industry: In chemical plants, centrifugal pumps are frequently preferred for mixing, transferring, processing and transporting chemical substances.

- Food and Beverage Industry: In the food and beverage industry, centrifugal pumps are used to process and transport liquid food products (e.g. milk, juice, beer, etc.).

- Power Plants: In power plants (nuclear, thermal, hydroelectric, etc.), centrifugal pumps are used in processes such as circulation of cooling water, boiler feed water, and waste water transportation.

- Maritime and Ships: In the maritime industry, centrifugal pumps are used for ballast water pumping, fuel transfer, and fire extinguishing systems on ships.

- Construction and Mining: Centrifugal pumps are used in construction, concrete mixers, and in mining, in operations such as water and mud transportation.

- Agriculture: In the agricultural sector, centrifugal pumps are used for irrigation systems and transportation of agricultural chemicals.

Due to the variety of applications in these sectors, industrial centrifugal pumps have a wide range of uses and are considered an essential component in many industrial processes.

Centrifugal Pump Working Principle:

- Suction Phase: The rotor located in the center of the pump begins to rotate. This rotation allows the liquid to be drawn towards the center. Thus, liquid is drawn from the suction pipe (inlet pipe) of the pump.

- Liquid Inflow: The liquid drawn from the suction pipe moves towards the inside of the pump and gains speed due to the rotational movement around the rotor.

- Effect of Centrifugal Force: The rotating movement of the rotor applies a centrifugal force to the liquid. This force causes the liquid to move outward. At this stage, the liquid is now pushed from the suction pipe and directed towards the pressure pipe (outlet pipe).

- Pressure Stage: Liquid is pushed out of the pump through the pressure pipe. Here the pressure of the liquid increases and is directed towards the desired target.

- Outflow: At the end of the pressure pipe, the liquid reaches the desired target. Here, the liquid is expelled from the pump and used in the desired system.

Related products

Hyginox SE Hygienic Centrifugal Pumps

Prolac HCP Centrifugal Hygienic Pumps

Dinfood High Capacity Centrifugal Pumps

DIN-FOOD Centrifugal Pumps, one of the High Capacity Food Processing Centrifugal Pumps, is a hygienic high capacity centrifugal pump capable of pumping up to 1000 m³/h, designed for use in the food processing, chemical and pharmaceutical industries.

It is mainly used in the beer, dairy and beverage industries and includes filtration processes. In addition, it can be used in some specific applications in the textile industry, chemistry, cosmetics and pharmaceutical industries.