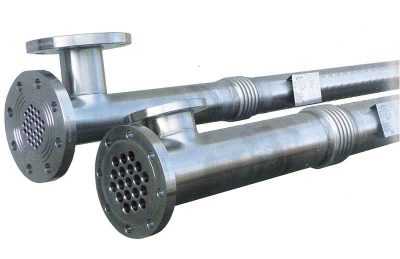

Food Industry Tubular Heat Exchangers

Food Industry Tubular Heat Exchangers (Food Industry tube heat exchangers) are the most used in all industrial plants for the transfer of thermal energy between different fluids. High Efficiency Heating and Cooling Applications in Industrial Processes.

FSTE-1 – Multi Pipe Single Pass Food Industry Tubular Heat Exchangers

Food Industry Tubular Heat Exchangers is especially suitable for food industry facilities where applications such as sterilizers-pasteurizers-UHT are involved.

Food Industry Tubular Heat Exchangers is especially suitable for food industry facilities where applications such as sterilizers-pasteurizers-UHT are involved.

It is possible to use multiple pipes in fixed plates made with different pipe types for these applications.

During construction, special attention is paid to the internal geometry, connection and surface level.

Various inspections during manufacture to ensure a high standard of quality

It is designed and built according to the careful study of working conditions to improve performance.

FSTE-2 – Single Tube Single Pass Food Industry Tube Heat Exchangers

Food Industry Tube Heat Exchangers is especially suitable for food industry facilities where applications such as sterilizers-pasteurizers-UHT are involved.

Food Industry Tube Heat Exchangers is especially suitable for food industry facilities where applications such as sterilizers-pasteurizers-UHT are involved.

For these applications, it is possible to use a single pipe in fixed plates made with different pipe types. During construction, special attention is paid to the internal geometry, connection and surface level.

During manufacture, various inspections are carried out to ensure a high standard of quality.

It is designed and built according to the careful study of working conditions to improve performance.

FSTE-3 – 4-Pipe High Pressure Tube Heat Exchanger

They are suitable for the food industry and for the sterilization of highly viscous products such as:

They are suitable for the food industry and for the sterilization of highly viscous products such as:

This type of heat exchanger provides excellent efficiency thanks to double contact chambers and an internal / external counter current, and provides extremely easy maintenance thanks to complete inspection

FSTE-4 – Sökülebilir Düz Demet Isı Eşanjör

This type of heat exchanger is especially suitable for food industry facilities where applications such as sterilizers-pasteurizers-UHT are involved.

This type of heat exchanger is especially suitable for food industry facilities where applications such as sterilizers-pasteurizers-UHT are involved.

During construction, special attention is paid to the internal geometry,

connection and surface level.

During manufacture, various inspections are carried out to ensure a high standard of quality.

It is possible to apply detachable pipe bundles in accordance with food standards.

It is designed and built according to the careful study of operating conditions to better match performance. Such heat exchangers are fully checked for better monitoring and cleaning.