Gasketed – Hygienic Plate Heat Exchangers

Gasketed – Hygienic Plate Heat Exchangers for Hygienic Applications.

Hygienic practices require a unique set of requirements to solve the problem and meet strong demands for cleanability, accessibility and product integrity. Our Gasketed – Hygienic Plate Heat Exchangers portfolio is known for its high quality and value adding features. With a wide range of frame compression technologies, connection types and hygienic accessories for increased cleanability, we can meet all heat transfer needs in the hygienic industries.

Gasketed – Hygienic Plate Heat Exchangers Application

APV hygienic plate heat exchangers solve a wide range of requirements in food processing and related industries that require high hygiene. Cleanability, accessibility and product quality are the distinguishing features of APV heat exchanger products. Take process hygiene and product safety to the next level with the Hygienic Heat Exchanger product group. This premium range of plate heat exchangers optimizes process hygiene and energy efficiency. It has been specially developed for hygienic applications and increases the level of hygiene to the highest level while reducing the carbon footprint for food applications, beverages applications, pharmaceuticals and other manufacturers that require extraordinary performance and efficiency.

Advantages of Sanitary Plate Heat Exchangers:

Advantages of Sanitary Plate Heat Exchangers:

- Variety of plate and gasket options to respond to aggressive fluid applications.

- Required with high thermal efficiency, saving money by reducing the heat transfer area.

- Provides up to 97% heat savings

- Eliminates the complex maintenance required for X-ray, ultrasonic and other non-destructive testing procedures

- Fixed parts eliminate vibration and reduce maintenance

- Lower investment cost compared to traditional piped system

- Space-saving with its compact design

- Reduces lifecycle cost

Hygienic Plate Heat Exchangers Materials

- Gasket Material

- Paradur (Fluoropolymer)

- Paracent (FDA compliant fluoropolymer

- EPDM

- Silicon

- Paratemp (EPDM hardening of the resin)

- EPDM hardening of peroxide

- ParaminePa

- ranile Paracil Paraprene

- Parator

- Plate Materials

- Stainless Steel (Gr. 304, 316, 317,304L, 316L)

- Alloy AL6XN ,

- Alloy 904L

- Alloy 27-7MO

- Alloy 254 SMO

- Nickel Alloys

- Nickel 200

- Alloy G-30

- Alloy B-2

- Alloy C-22

- Alloy C-276

- Alloy C-2000

- alloy 33

- Others

- Titanium (Gr.1)

- Titanium Palladium (Gr. 7 and 11)

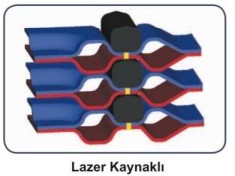

Welded Plate Pairs

APV’s laser welded plate pairs have a wide range of plates for the chemical processes and refrigeration industry. Therefore, it is a suitable alternative to all other welded and tube heat exchangers. Plate pairs are suitable for evaporation and condensation applications. It is a suitable solution for aggressive fluids against sealing in the chemical industry.

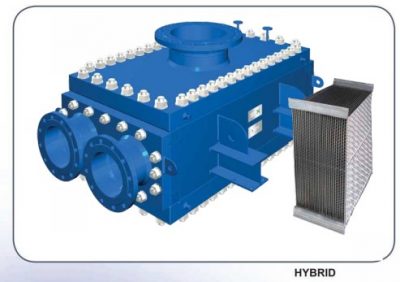

APV HYBRID

It provides a heating surface density of 250 m2/m3 with its compact design. It provides heat transfer in gases as well as special fluids. Another advantage over tube heat exchangers is the high economic efficiency of the APV HYBRID Heat Exchanger. Significant cost reductions are possible by using less material with higher grade alloys. – Working conditions -200°C +900°C) – Working pressure: 60 bar

- Completely gasketless

- 6000 m2 Heat transfer area per unit

- High heat transfer even at low pressure losses

- Self-cleaning with high turbulence

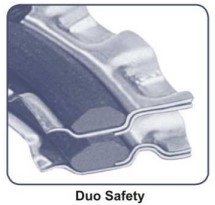

Duo Safety Plate Heat Exchangers

APV’s Duo safety Plate system will provide you with protection against mixing fluids within the plates as a result of plate cracks. Thus, the leakage in the plate cracks will be forced out of the plate heat exchanger. This patented product arises from the formation of a single plate by joining two identical plates to each other without welding. Each double plate is sealed with a non-adhesive Para-Clip gasket.

Other Advantages

- 100% visual detection

- The plates can be separated for easy cleaning on both sides during cleaning.

- Flexibility to use different Gasket and Plate material in plate pairs, For example: Stainless Steel / Titanium plates or EPDM / Viton gaskets

Related products

Gasketed – Industrial Plate Heat Exchangers

The global applications for industrial heat exchangers calls for a wide and deep product range, putting great demand on the equipment. SPX FLOW's portfolio of APV ParaFlow is designed to satisfy your needs, whether this is for very small flows, or the extra-large kind, up to 4500 m3/h. With our selection of materials, connections and accessories, we can supply equipment for practically every heat transfer need. The ParaWeld and Paramine technologies expand the boundaries for gasketed plate heat exchangers. Added our long experience in after sales services, SPX FLOW is your all-round partner for heat transfer.