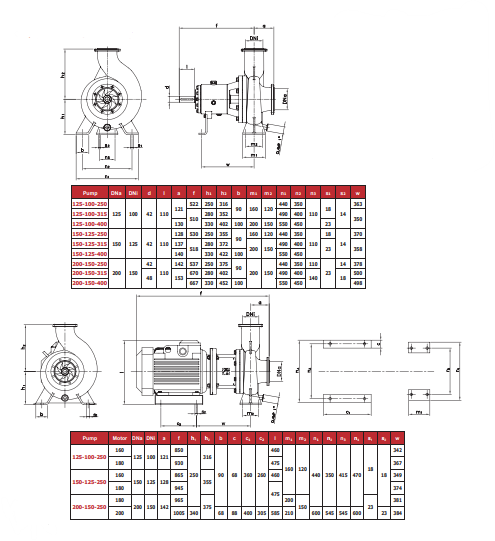

Dinfood High Capacity Centrifugal Pumps

DIN-FOOD Centrifugal Pumps, one of the High Capacity Food Processing Centrifugal Pumps, is a hygienic high capacity centrifugal pump capable of pumping up to 1000 m³/h, designed for use in the food processing, chemical and pharmaceutical industries.

It is mainly used in the beer, dairy and beverage industries and includes filtration processes. In addition, it can be used in some specific applications in the textile industry, chemistry, cosmetics and pharmaceutical industries.

DIN-FOOD Centrifugal Pumps Application

The DIN-FOOD Centrifugal Pumps are hygienic high capacity centrifugal pump (up to 1000 m³/h) designed to cater for an unfulfilled need in the food-processing and chemical and pharmaceutical industries. The applications of the high-flow centrifugal pump include processes in the brewing, dairy and beverage industries in general, as well as in ultra-filtering processes. It can also be used in the textile industry and in some specific processes in the chemical, cosmetics and pharmaceutical industries.

Operating Principle

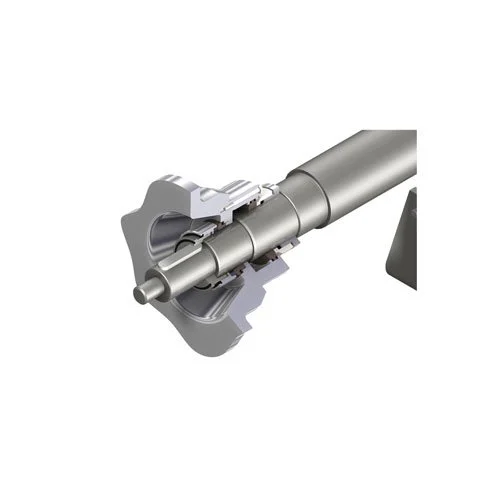

Housed inside the casing, the impeller rotates in conjunction with the pump shaft. With this arrangement, the impeller blades convey energy to the fluid in the form of kinetic energy and pressure energy. This pump is not reversible by a simple reversal of the direction of rotation. The direction of rotation is clockwise when the pump is viewed from the rear side of the motor.

DIN-FOOD Centrifugal Pumps Design and Features

- Casing with volute manufactured with 8 mm cold-formed plate.

- Aseptic flanges according to DIN 11864-2.

- Double curvature impeller with blades on the rear side to reduce the axial

- thrust.Axial adjustment of the impeller (bare shaft version). Hygienic mechanical seal.

- Fully drainable pump.

- Designed according to the EHEDG standards.

- IEC B3 motors (B35 close-coupled constructions),

- IP 55, F-class insulation..

Materials :

Parts in contact with pumped media: AISI 316L

Lantern and bearing support: CF8 / GG-22

Gaskets: EPDM according to FDA 177.2600

Mechanical seal: SiC/C/EPDM

Inside surface finish: Ra ≤ 0.8

Outside surface finish: satin

Technical specifications

Max.flow: 1000 m³/h 4403 US GPM

Max.differential head: 90 mwc 295 ft

Max.operating pressure: 10 bar 145 PSI

Max.working temperature: -10 ºC to +120 ºC (EPDM) 14 ºF to 248 ºF

+140 ºC (SIP, max. 30 min) 284 ºF

Max.speed: 1800 rpm

3600 rpm (model 125-100-250/2)

Options

- Close-coupled construction for models 250.

- Mechanical seal in SiC/SiC for abrasive materials.

- Tandem type mechanical seal and pressurized double mehcanical seal.

- Gaskets: FPM and PTFE.

- Industrial finish (DIN-TEX).

- Motor shroud.

- Motors with additional protection.

- Stainless steel base plate.

- ATEX version available.