Mix Blend Horizontal Blender

MixBlend Horizontal Blenders are used to add solids that tend to clump when mixed with liquids. The advantage of this blender, unlike many other blender models, is that it is suitable for use with products containing higher concentrations of gum and thickeners. Ideal for solids such as gums, pectins and other thickening agents. The scope of application is limited to the addition of small quantities of solids that quickly disperse and break up into the product.

Mix Blend Horizontal Blender Application

Mixblend blenders are used to add solids that tend to clump when mixed with liquids. Unlike many other blender models, the advantage of this blender is that it is suitable for use with products with higher concentrations of gums and thickening agents. It is ideal for solids such as gums, pectins and other thickening agents. Its field of application is limited to adding small amounts of solids that are dispersed and sheared quickly into the product.

Mix Blend Blender Operating Principle

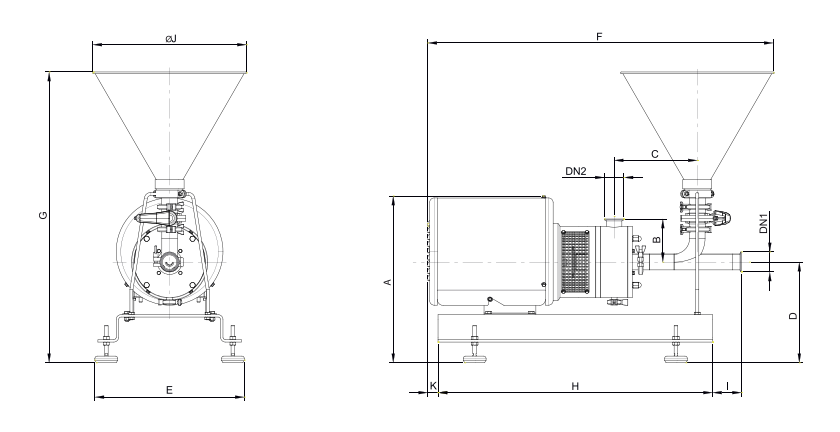

The Mixblend Horizontal Blender is a compact unit, comprised of an in-line mixer with a venturi system for suction and a hopper with a butterfly valve above the venturi system to add the solids to the liquid flowing through the mixer. The suction and venturi system are set horizontally in this blender.

The venturi system creates negative pressure at the base of the hopper. When the hopper valve opens, the solids are drawn and easily dissolved as they pass through the mixer housing.

It is recommended to recirculate the product (batch production) until all the solid/powder product is suctioned in and then, when the solid product is completely incorporated into the liquid product, continue recirculating the product for a while to ensure the most homogeneous dissolution possible.

Design and Features

- Simple and versatile unit for fast and homogeneous mixing of a wide range of solids without any contact with the air.

- Hygienic design.

- Single mechanical seal.

- ISO 2852 Clamp connections for easy assembly/disassembly.

- Butterfly valve for the hopper.

- Cleaning and disinfection without disassembly.

Technical Specifications

Materials:

- Parts in contact with the product : AISI 316L

- Other metal parts : AISI 304

- Gaskets : EPDM

Mechanical seal :

- Rotary part : Silicon carbide (SiC)

- Stationary part : Silicon carbide (SiC)

- Gaskets: EPDM

Surface finish :

- Internal: Bright polish Ra ≤ 0,8 Μm

- External : Matt

Horizontal BlenderOptions

- Double mechanical seal.

- Gaskets in FPM or PTFE.

- DIN, SMS connections.

- Drain port.

- Vibrator for hopper.

- Pneumatically actuated valve + hygienic low level sensor for solids.

- Hygienic upper level sensor for solids.

- Control panel for the vibrator, level sensors and automatic valve.

- Mounted on a cart with or without control panel.

- Grid for the hopper

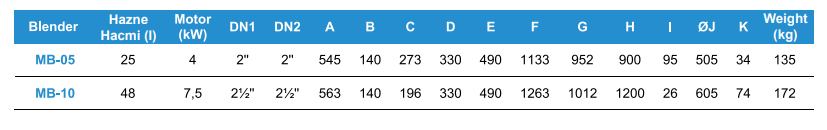

| Blender | MB-05 | MB-10 |

| Approximate flow rate | 20 m³/h | 30 m³/h |

| Maximum solids intake | 1300 kg/h* | 2000 kg/h* |

| Blender base | ME-4105 | ME-4110 |

| Hopper capacity | 25 litres | 48 litres |

| Motor (3000 rpm) | 4 kW | 7.5 kW |

| Maximum temperature | 65ºC | |

| Connections (suction/propulsion) | CLAMP | |

| Hopper valve | CLAMP (butterfly valve) | |

* The intake of solids can vary depending on their properties

Related products

MM Table Blender

The MM Table Blender is used to dissolve solids and powders. It has a wide range of uses, such as the production of marmalade, the preparation of pharmaceutical syrups or the dissolution of pectin in glucose. Common use applications are diluting or stabilizing milk in dairy production and dissolving sugar for syrup production in the beverage industries.

MH Horizontal Blender

M-226 / M-440 Powder Liquid Vertical Blender

Liquid-Powder vertical blenders designed for powder-liquid mixtures are made of 316 L material in different capacities. It provides the mixture of powder raw material with liquid, especially in the food and dairy sectors, by circulating quickly.

M440-M226 Liquid Powder Blender is used to mix solids into liquids.

In the food processing industry, it is used to dilute milk powder, make syrup, prepare brine, etc. They offer the perfect solution for They can also be used in the preparation of solid-liquid mixtures in the pharmaceutical, cosmetic and chemical industries.