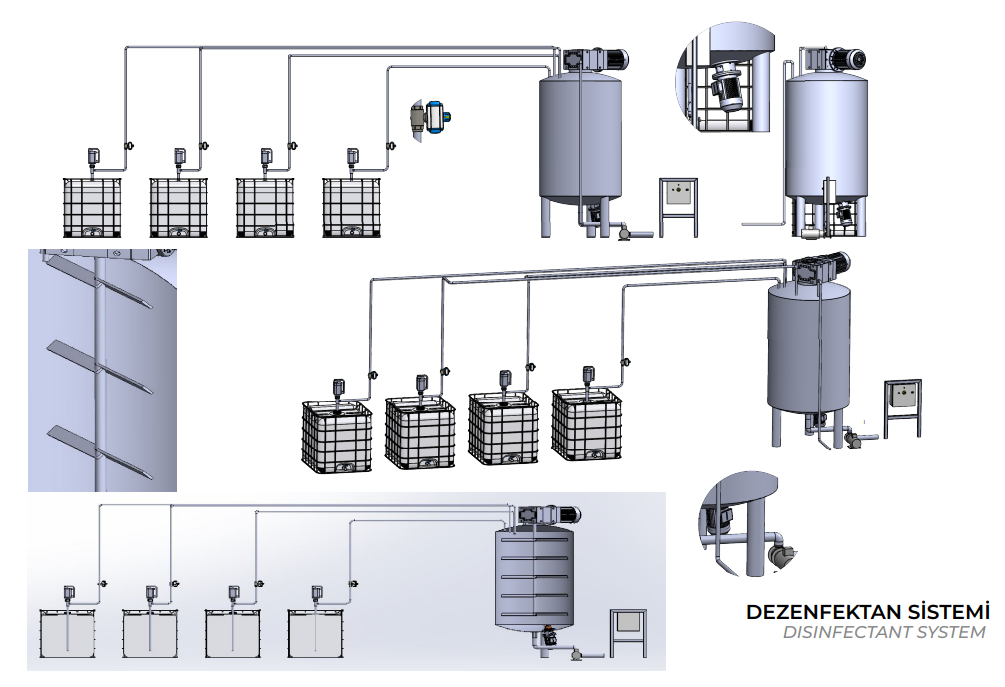

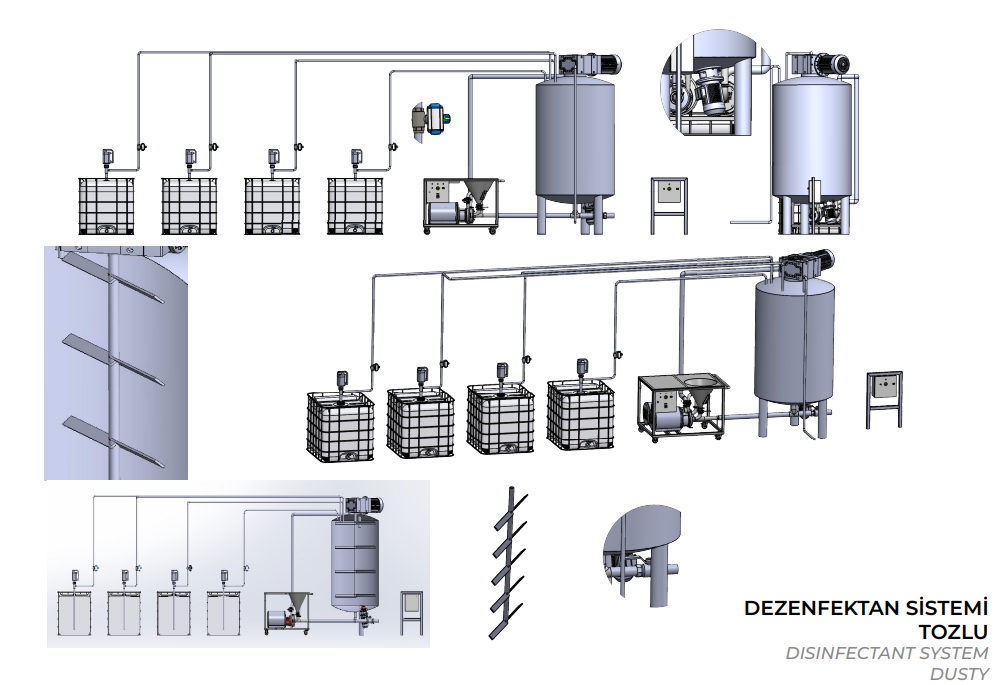

Disinfectant Unit

The Disinfectant Unit includes a sealed tank where the mixing is performed by means of a central agitator (and a radial agitator, if necessary). The lid has an opening which is used for inspection and material loading, the diameter of which is in correspondence with the capacity of the unit. Furthermore, the lid also holds the agitator, with or without lifting mechanism. The agitator speed is controlled by an electronic variable speed drive.

The Disinfectant Unit, includes a rotary lobe, progressive cavity or centrifugal pump to transport the product from the tank to the exterior or to an intense agitation system, of a disperser, emulsifier, or solid-liquid mixer type.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions

Disinfectants; They are a type of cleaning product that kills germs and disinfects surfaces. These products are often used in industries such as schools, hospitals, medical clinics, food, beverage, cosmetics, personal care and biotechnology. Disinfectants react chemically to kill germs, mold, and odor and disinfect surfaces. First, it is recommended to clean all surfaces with detergent and water to remove chemicals left behind by disinfectants.

Disinfectants; They are a type of cleaning product that kills germs and disinfects surfaces. These products are often used in industries such as schools, hospitals, medical clinics, food, beverage, cosmetics, personal care and biotechnology. Disinfectants react chemically to kill germs, mold, and odor and disinfect surfaces. First, it is recommended to clean all surfaces with detergent and water to remove chemicals left behind by disinfectants.