Application

The Steripig Product Recovery System is ideal for the recovery of any product remaining in a pipeline at the end of the transfer process. As this product can be of a high value the PIG system recovers the product removing it from the pipelines and preparing the pipeline for a CIP process. Another benefit is the reduction of the fluid sent to the sewage treatment plant that results in saving energy and water.

The main application of the system is viscous media. Among the products treated there are gels, creams, ointments, emulsions and other products of high value in the pharmaceutical or cosmetic industry.

Steripig Product Recovery System Operating Principle

The STERIPIG system offers a completely hygienic product recovering solution because no component enters or leaves the installation. The sphere is positioned by external magnet. During the CIP process, when the flow rate is sufficient, the sphere gets free inside the launcher or receiver avoiding any dead leg zones between the pipeline and the sphere.

The system includes a launcher, a receiver, a PIG (a sphere), two position detectors (one for the launcher and the other for the receiver), four automatic butterfly valves and two KH three way valves.

The process starts locating the sphere in the launching position. Then the sphere is driven by a propellant (normally compressed air) down the pipeline to the receiver recovering any product left in the pipeline. When recovery is complete, the PIG is situated at the receiver and all the installation can be cleaned by CIP, the PIG can also be cleaned during the CIP routine. The CIP process is finished, the sphere is placed again into the launcher leaving the plant ready for the next production process.

Design and features

PIG can pass through 1.5D bends.

PIG can pass through 1.5D bends.- Connections: Clamp OD (standard).u

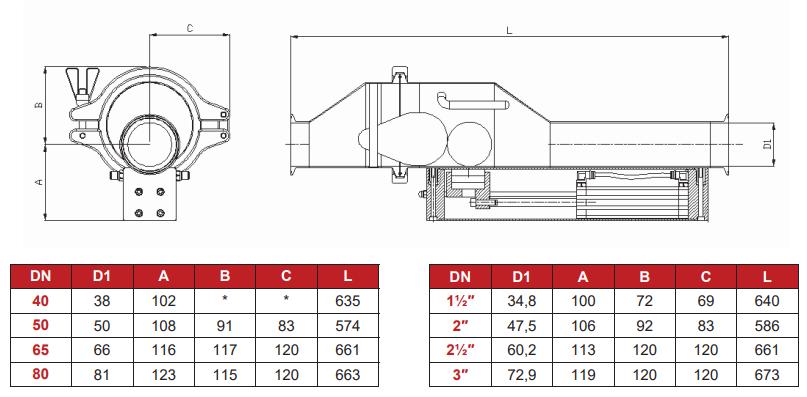

- Size ranges: From 1 ½” (DN 40) to 3″ (DN 80).

- Hygienic design according to the EHEDG specifications.

Materials

- Metal parts in contact with the product: AISI 316L

- Other metal parts: AISI 304

- PIG: Silicone

- Gasket: EPDM according to FDA 177.2600

- Internal surface finish: Ra ≤ 0,5 µm

Options

- Connections: DIN, RJT, SMS, etc.

- Spheres: EPDM and Viton®.

- Gaskets: Silicone, PTFE, Viton®.

- Various levels of automation.

- Control panel.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions