Stainless Steel Seamless Pipes

Stainless steel seamless pipes are pipes made of stainless steel material. Draw pipes are widely used in the chemical, oil and gas industry, water and wastewater treatment plants, marine, food processing, medical devices and many other industries. You can obtain Hygienic and Industrial Stainless Steel Seamless Pipes from our company.

Application of stainless steel seamless pipes

Stainless steel seamless pipes are pipes made of stainless steel material and without a joint line. These pipes are widely used in the chemical industry, oil and gas industry, water and wastewater treatment plants, marine, food processing, medical devices and many other industries.

Stainless steel seamless pipes are widely used in many different industries. Some examples are:

- Chemical Industry: It is used for the production, storage and transportation of chemicals.

- Oil and Gas Industry: Used to build pipelines for oil, natural gas and other hydrocarbons.

- Water and Wastewater Treatment Plants: It is used in water treatment plants, pipelines and wastewater plants.

- Marine: Stainless steel seamless pipes are used in submarine pipelines, shipbuilding and other marine applications.

- Food Processing: It is used in the food processing industry, for example, for the production of milk and dairy products.

- Medical Devices: It is used in the production of many components used in medical devices.

- Other Industries: Stainless steel seamless pipes are also used in many different industries such as nuclear power plants, aerospace industry, automotive industry, construction industry.

Manufacture of Seamless Pipes

Seamless Steel Pipesare produced by rolling heated (baked) billet. At high rolling speed and pressure, the configuration creates pressure in the center of the slab and pierces with a pointed rod creating the tube sleeve. This sleeve is then extended on a multi-roll stand with a mandrel or a long bar, inserted into the tube to achieve the desired range of wall thickness and diameter.

Thanks to their homogeneity in microstructure, the strength of seamless pipes is higher than the welded pipes produced by sheet bending and welding, but their production costs are higher.

Advantages of stainless steel drawn pipes

The advantages of stainless steel seamless pipes include high strength, corrosion resistance, high temperature resistance and long life. In addition, the smooth inner surface of the seamless pipes ensures fluidity and low pressure loss.

Along with these, stainless steel seamless pipes have many advantages. Some of them are:

- Corrosion Resistance: Stainless steel seamless pipes are highly resistant to corrosion and are therefore a reliable option for pipelines carrying liquids or gases.

- High Strength: Stainless steel seamless pipes are durable even under heavy loads thanks to their high strength properties.

- igh Temperature Resistance: Stainless steel seamless pipes are durable even in high temperature environments.

- Low Maintenance: Stainless steel seamless pipes require low maintenance and have a long service life.

- Aesthetic Appearance: Since the surface of stainless steel seamless pipes is smooth and shiny, it is also preferred in terms of aesthetics.

- Fluidity: Since the inner surface of seamless pipes is smooth, fluidity is ensured and pressure loss is low.

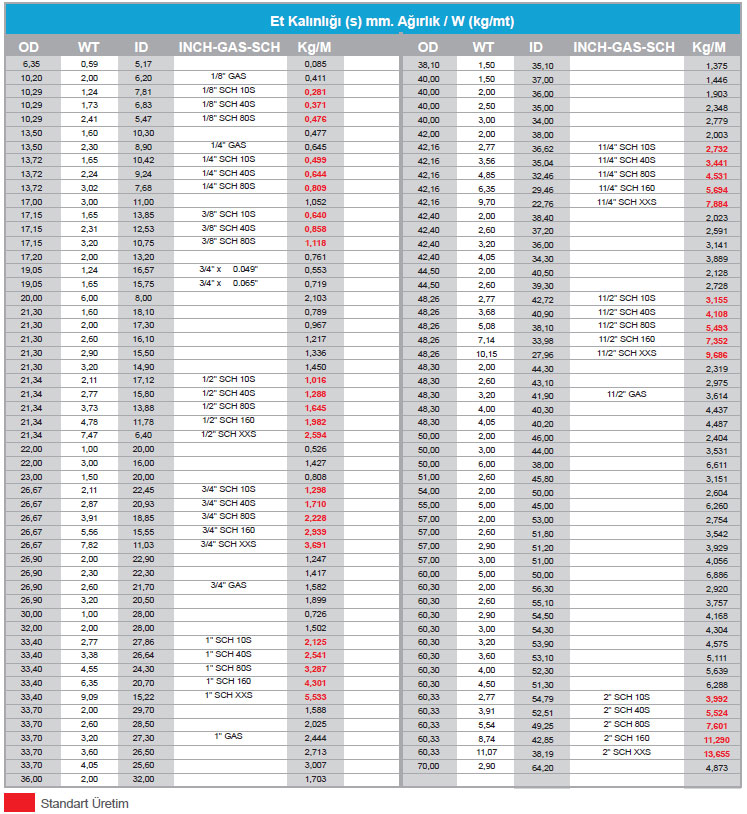

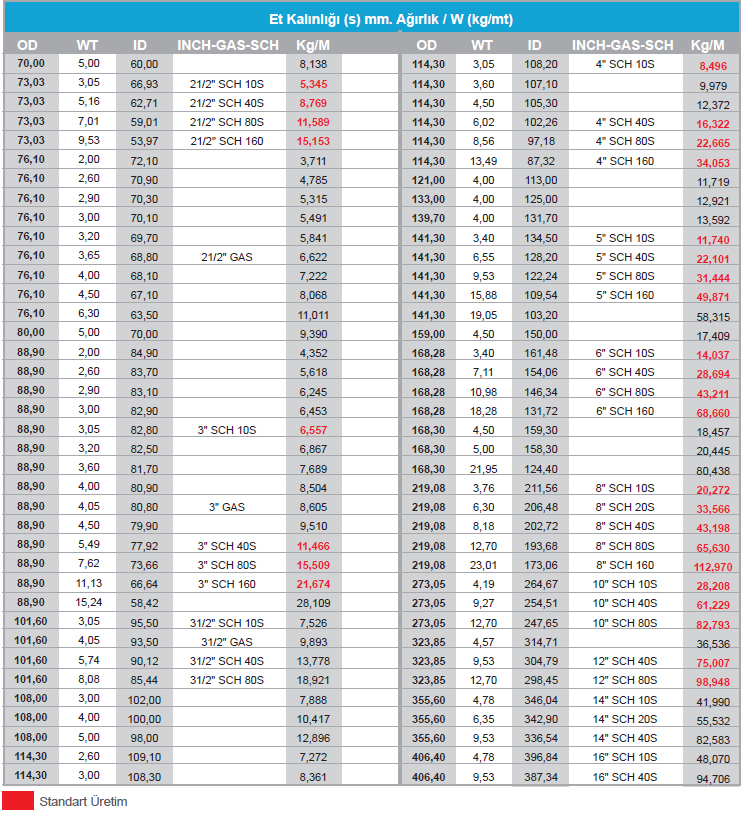

- Wide Variety of Sizes and Thicknesses: Stainless steel seamless pipes can be custom made with a wide variety of sizes and thicknesses, so they can be used in different industries to suit different needs.

Stainless steel seamless pipes are available in various sizes and thicknesses and can be custom-made according to the customer’s needs.