Pharmaceutical Industry Applications

Use of Heat Exchanger in Pharmaceutical Industry Applications; The pharmaceutical industry is a sensitive sector that provides the production of products that are critical for human health. The quality, safety and stability of products are of great importance in this sector. Temperature control plays a major role in many processes in pharmaceutical production, and the use of heat exchangers in these processes is widely preferred in industrial applications. The pharmaceutical industry is a sector that is in constant growth trend and needs more sterile, faster and more sensitive processes every day. Heat exchangers, like all used systems, are widely used in the pharmaceutical industry to indirectly heat and cool contents during processes such as bulk drug processing, batch reactions and crystallization.

What is Heat Exchanger?

Heat exchangers are devices that enable heat transfer between two fluids. They are generally used for cooling or heating purposes in the pharmaceutical industry. Two different fluids come into contact through the plates or tubes inside the exchanger, and thus heat transfer occurs. Heat exchangers are useful devices designed for efficient heat transfer between two fluids at different temperatures. Heat exchangers are widely used in the food processing industry, dairy industry, biochemical processes, pharmaceutical products, chemical applications and petroleum facilities. The use of heat exchangers in the pharmaceutical industry; It is quite common, from high temperature pasteurization to low temperature freezing.

Heat Exchanger Types

Heat Exchanger Types

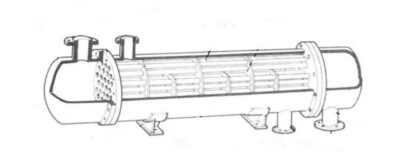

Tube heat exchanger: It consists of a series of tubes containing the liquid that needs to be heated or cooled, and the second fluid is circulated over the pipes that need to be heated or cooled. Tubular heat exchangers are often used in high-pressure applications due to their durability. The figure on the right shows a typical tube heat exchanger.

Plate heat exchanger: It is a heat exchanger that is widely used in a wide variety of chemical processes and other industrial applications, especially in the food industry, for various reasons such as its compact design and a very large surface area on a small volume. Changes can be made according to need by increasing or decreasing the number of plates. It consists of several thin plates spaced apart, providing a passage for fluid flow for heat transfer. The figure on the left shows a plate heat exchanger.

Plate heat exchanger: It is a heat exchanger that is widely used in a wide variety of chemical processes and other industrial applications, especially in the food industry, for various reasons such as its compact design and a very large surface area on a small volume. Changes can be made according to need by increasing or decreasing the number of plates. It consists of several thin plates spaced apart, providing a passage for fluid flow for heat transfer. The figure on the left shows a plate heat exchanger.

The Role of Exchangers in Pharmaceutical Production

-

Temperature Control in Reactors: In drug production, reactors generally operate within certain temperature ranges. Heat exchangers are used to keep the temperature of the reactors at the desired level. This ensures stable and high-quality production of products.

-

Product Cooling and Heating: In pharmaceutical production, products formed as a result of a reaction may be hot or cold. Heat exchangers are used to bring these products to desired temperature levels. Some drugs in particular have high temperature sensitivity and therefore accurate temperature control is critical.

-

Steam and Cooling Water Rounding: Large amounts of steam and cooling water are generally used in pharmaceutical production facilities. Heat exchangers can be used to recover steam and cooling water. This reduces energy costs and makes the facility more sustainable.

-

Recovery of Solvents: Solvents are used in some pharmaceutical manufacturing processes. Heat exchangers can be used to recover these solvents. This reduces costs and reduces environmental impact.

Advantages of Using Heat Exchangers in Pharmaceutical Industry Applications

- Efficiency: Pharmaceutical Industry Heat Exchangers increase production efficiency by providing precise temperature control.

- Cost Reduction: Exchangers reduce costs by reducing energy costs and increasing process efficiency.

- Product Quality: Accurate temperature control improves product quality and ensures a stable product.

- Environmental Impact: The use of heat exchangers reduces environmental impact by providing energy recovery and process efficiency.

Use of Heat Exchanger in Pharmaceutical Industry Applications

- Antibiotic water

- Culture sterilizers

- Sterile water

- Cosmetic

- Shampoos

- Conditioners

- Creams

- Mouthwashes

- Mineral and baby oil

- Starches

Conclusion

Use of Heat Exchanger in Pharmaceutical Industry Applications is of great importance in terms of temperature control, energy efficiency and product quality. Correctly designed and operated exchangers optimize production processes and make facilities more sustainable. Therefore, the effective use of heat exchangers in pharmaceutical production facilities is an important practice in the industry.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions