Equipment Cooling With Sea Water

Equipment Cooling with Sea Water and Heat Exchangers Used on Ships

Equipment Cooling With Sea Water; The heated fresh water coming from the engine is cooled by sea water circulating in plate heat exchangers and sent back to the engine and other equipment.

Sea water is a cooling method used to reduce temperature. Using seawater for equipment cooling is a widely preferred method, especially on large ships. Seawater has a large cooling capacity and can be used as a natural coolant.

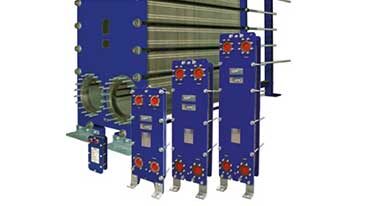

Plate Heat Exchangers

Stainless Steel Connection Equipment

Equipment Cooling Application with Sea Water

There are two basic methods of cooling equipment using seawater: direct use of seawater and closed-loop cooling with seawater.

- Direct Seawater Use: In this method, the equipment is cooled directly with seawater. Seawater is brought to the equipment with the help of a pump and temperature transfer is provided. In this method, seawater must be filtered and cleaned because the salts and sediments present in seawater can damage the equipment. Additionally, appropriate precautions must be taken to ensure that organisms present in seawater do not damage the equipment.

- Closed Circuit Cooling with Sea Water: In this method, sea water circulates in a closed circuit system and cools the equipment indirectly. Heat transfer occurs as seawater passes through the equipment with the help of a heat exchanger. In this method, since the equipment does not have direct contact with sea water, problems caused by salt and sediments are minimized. Additionally, appropriate precautions must be taken to prevent organisms found in seawater from entering the system.

Seawater equipment cooling can be an environmentally friendly option because it uses seawater, a natural coolant source. However, there are some potential disadvantages to using seawater. These include factors such as the fact that salt and sediments in sea water can damage equipment, sea water can cause corrosion, and the necessity of establishing and maintaining sea water infrastructure. Therefore, when choosing a seawater equipment cooling method, careful consideration should be made and appropriate precautions should be taken.

Seawater equipment cooling can be an environmentally friendly option because it uses seawater, a natural coolant source. However, there are some potential disadvantages to using seawater. These include factors such as the fact that salt and sediments in sea water can damage equipment, sea water can cause corrosion, and the necessity of establishing and maintaining sea water infrastructure. Therefore, when choosing a seawater equipment cooling method, careful consideration should be made and appropriate precautions should be taken.

Equipment Cooling with Sea Water Process and Heat Exchangers

Heat exchangers are frequently used on ships to cool equipment with sea water. These exchangers are used to reduce the temperature of sea water and equipment inside the ship. This process is vital for cooling various equipment such as ship engines, generators, compressors.

There are two main types of heat exchangers generally used on ships:

- Plate Heat Exchangers: This type of heat exchangers consists of metal plates tightly connected to each other. While sea water circulates between the plates, the hot water of the equipment also passes through different channels. In this way, heat transfer is achieved and the equipment is cooled.

- Shell and Tube Exchangers: In this type of exchangers, intertwined tubes are placed in a shell, and sea water passes through the shell region and the hot water of the equipment passes through the tubes. In this way, heat transfer occurs through the pipes.

Equipment Cooling With Sea Water system generally works like this:

- Seawater intake: Seawater is taken from the ship and directed to the exchanger system. Seawater is the main cooling source to be used for the cooling process in the exchanger.

- Equipment cooling water circulation: The water inside to be used for cooling the equipment is sent to the heat exchanger to reduce the temperature of the equipment.

- Heat transfer: Seawater and equipment cooling water come into contact with each other in the exchanger. Meanwhile, the hot water coming from the equipment transfers heat to the sea water circulating in the exchanger. In this way, the temperature of the equipment decreases.

- Return of chilled water: The chilled water passing through the exchanger is sent back to be used for cooling the equipment.

Equipment Cooling With Sea Water process is repeated continuously to keep the operating temperatures of the various equipment on the ship under control. In this way, overheating and damage to equipment is prevented and the ship continues to operate safely and efficiently.