Ethylene Oxide Production

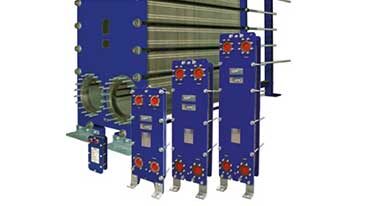

It is a colorless, odorless, light and flammable gas and consists of the reaction of ethylene oxide, ethylene and oxygen used in the production of ethylene glycol and sterilization of food and medical products at a temperature of 200-3000 C. Ethylene oxide is produced from ethylene using air or oxygen. Compressed air or oxygen, ethylene and recycle gas are mixed and fed into the catalytic reactor. The waste gases containing ethylene are discharged from the oxide reactor. The cooled and compressed gases are absorbed by a scrubber as a dilute aqueous solution of ethylene oxide. The unabsorbed gases are returned to the reactor and a closed circuit is completed. Most of the ethylene oxide produced is used for ethylene glycol production. During these processes, we provide quality and reliable services in the field with our wide range of products and plate heat exchangers.