Aspir Self-Priming Pumps

ASPIR Self-Priming Pumps are suitable for use in food processes, pharmaceutical and chemical industries. It is generally used for the transfer of products at temperatures close to the boiling point such as oil, wine, alcohol, acetone. Its main application is as a CIP return pump.

Gear pump with self-priming feature can transfer the product by sucking from a distance of 4-5 meters. It is extensively used in CIP systems, food applications and fluid transfers containing steam.

ASPIR Self-Priming Pumps Application

Aspir Self-Priming Pump is a sanitary side-channel self-priming pump suitable for use in the food-processing, pharmaceutical and chemical industries. It is specially designed for pumping products containing air or gas, and it can also be used for negative suction with prior priming as well as in filtration equipment.

It can be used to pump wine, oil, syrups, volatile products such as alcohol, acetone and other solvents, or products at temperatures close to the boiling point. However, the main use of this pump is for CIP return.

Operating principle

The impeller is housed between the suction casing and the diffuser, it rotates in conjunction with the pump shaft. Due to this arrangement, the rotation of the impeller and the position of the side channel, negative pressure is created inside the suction casing, which generates the suction force of the pump. At the same time, the fluid receives energy in the form of kinetic energy and pressure energy, and this impels it through the discharge casing

side-channel Design and features

Aspir Self-Priming Pump is a range of centrifugal pumps made of a cold-formed stainless steel discharge casing, cast sainless steel suction casing, diffuser and lantern, star-shaped fixed impeller, and an external mechanical seal that prevents any contact of the spring with the product.

The motor complies with the IEC standards, it is protected with a stainless steel shroud made of stainless steel sheet and provided with the height adjustable hygienically designed legs

Technical specifications

Materials:

Parts in contact with the product: Stainless steel AISI 316L (1.4404)

Other steel parts Stainless steel: AISI 304 (1.4301)

Gaskets in contact with the product: EPDM

Mechanical seal:

Rotary part: Silicon carbide (SiC)

Stationary part: Carbon (C)

Gaskets: EPDM

Surface finish:

External: Matt

Internal: Bright polish except for electropolished impeller

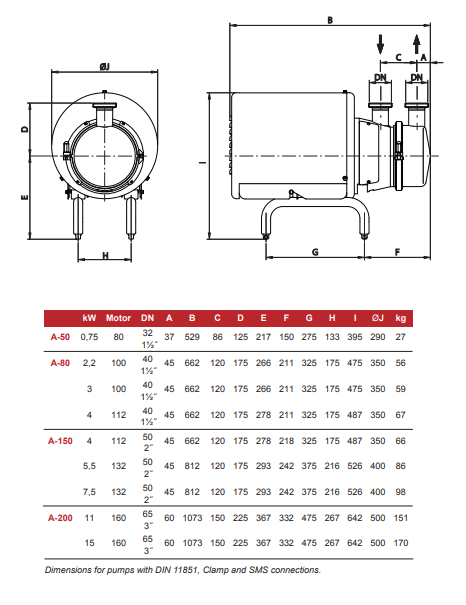

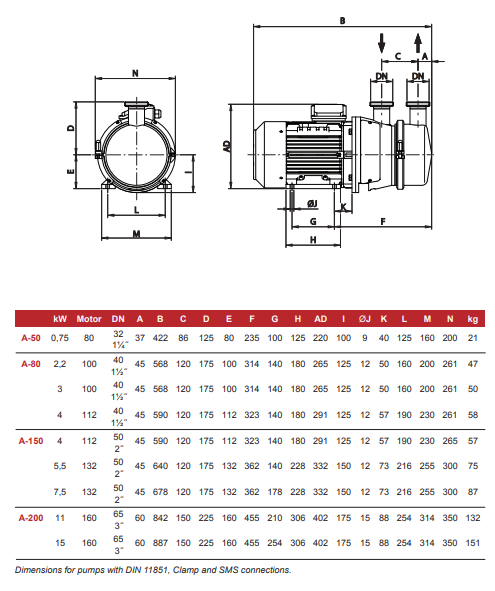

Connections:

- DIN 11851

- Aseptic flange DIN 11864

- CLAMP

- SMS

- (other connections available on request)

Operating limits: :

Nominal pressure: 1000 kPa (10 bar) 145 PSI

Temperature range :

-10°C to +120 °C 14 °F to 248 °F

+140°C (SIP, max.30 min.) 284 °F

Maximum flow: 54 m³/h 238 US GPM

Maximum differential head: 50 m 164 ft

Maximum suction height: 4 m 13 ft

Maximum speed: 1800 rpm

Motor

- Triphasic induction motor with B5 flange and B3 legs, in compliance with the IEC standards,

- 4 poles = 1500/1800 rpm, IE-2 / IE-3 efficiency class, IP 55 protection and F-class insulation.

3 phases, 50 Hz, 220-240 V Δ / 380-420 V Υ, ≤ 4 kW

3 phases, 50 Hz 380-420 V Δ / 660-690 V Υ, ≥ 5,5 kW

Side Channel Pump Options

- Heavy-duty impeller.

- Pump casing with drain port.

- Different types of connections.

- SiC/SiC mechanical seal.

- Gaskets: FPM and PTFE.

- Motor with other voltages and frequencies.

- Motor for explosive atmospheres or with enhanced safety level.

- ATEX certification.

- Internal flow by-pass.

Options

- Heavy-duty impeller.

- Pump casing with drain port.

- Different types of connections.

- SiC/SiC mechanical seal.

- Gaskets: FPM and PTFE.

- Motor with other voltages and frequencies.

- Motor for explosive atmospheres or with enhanced safety level.

- ATEX certification.

- Internal flow by-pass.