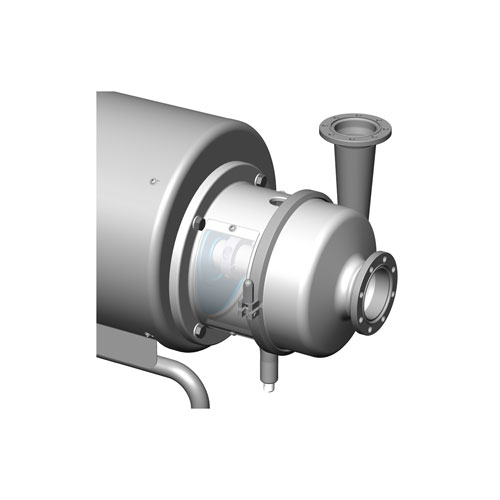

Prolac HCP Centrifugal Hygienic Pumps

Due to its material selection and design, the Prolac HCP Centrifugal Hygienic Pumps are suitable for applications requiring a high level of hygiene and offers resistance to chemical substances by providing sensitive processing of the product.

Hygienic Pumps Application

Due to the choice of materials and its design, PROLAC HCP Centrifugal Hygienic Pumps are appropriate for applications requiring a high level of hygiene, it offers gentle handling of the product and resistance to chemical agents.

It is particularly suitable as main process pump in the dairy, beverage, pharmaceutical and cosmetic industries.

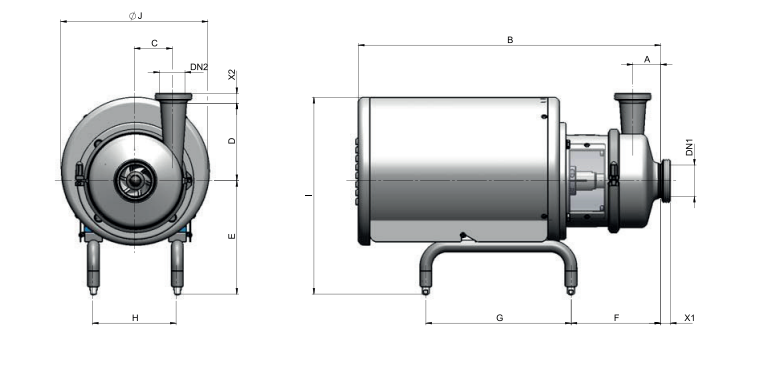

Prolac HCP Centrifugal Hygienic Pumps Design and Features

PROLAC HCP is a range of close-coupled centrifugal pumps with hygienic design, compact and highly efficient. It is made of a cold-formed stainless steel casing, impeller, mechanical seal, pump cover, lantern and shaft, connected to the motor shaft by mechanical compression.

The motor complies with the IEC standards, it is protected with a stainless steel shroud and provided with the height adjustable hygienic designed legs.

Hygienic Pumps are EHEDG certified, it is especially designed for CIP/SIP without disassembly The pump is authorized to carry 3-A symbol.

Note: Consult the options of the pumps authorized to carry 3-A symbol.

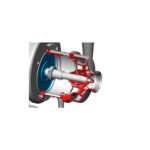

Mechanical Seal

The PROLAC HCP Hygienic Pumps is provided with an internal single mechanical seal. The seal is balanced and has a hygienic design. As standard, the stationary part is in carbon and the rotary part is in silicon carbide, the gaskets are in EPDM.

However, when required, other material can be used. There is also an option of assembly of a double mechanical seal made of two identical seals. It helps to upgrade a pump with single seal to double seal and simplifies the mangement of necessary spare parts as the seal is the same

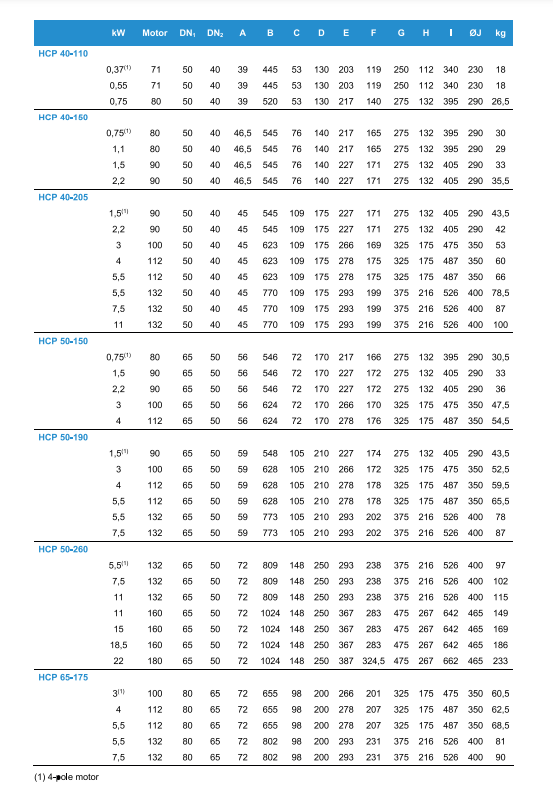

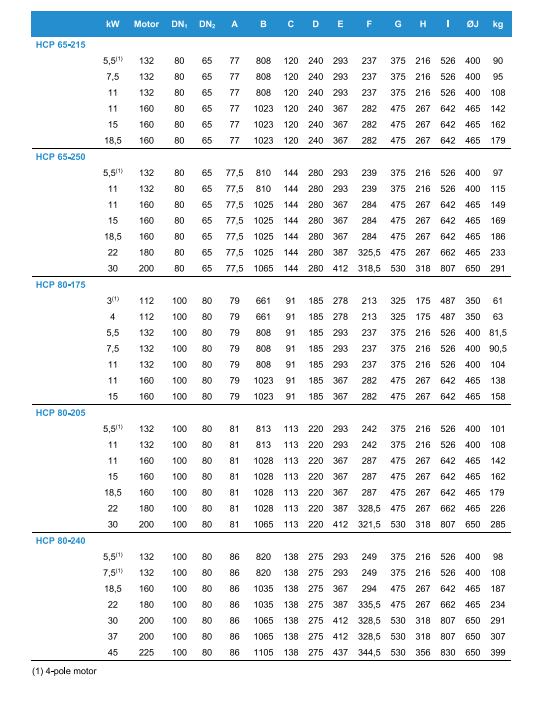

Prolac HCP Centrifugal Hygienic Pumps Technical Specifications

Materials

Parts in contact with the product: : Stainless steel AISI 316L (1.4404)

Other metal parts : Stainless steelAISI 304 (1.4301)

Gaskets in contact with the product: EPDM

Mechanical seal :

Rotary part: Silicon carbide (SiC)

Stationary part: Carbon (C)

Gaskets: EPDM

Surface finish:

External: Matt

Internal: PBright polish R<0,8μm

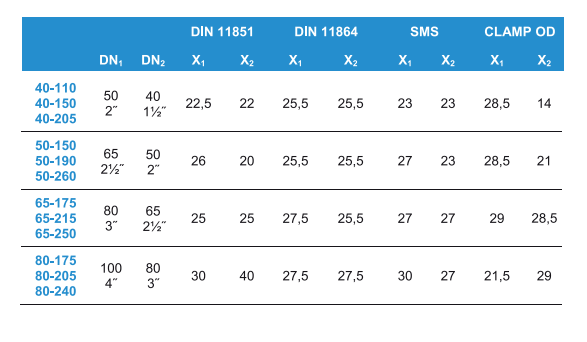

Connections: DIN 11851

Aseptic flange: DIN 11864

CLAMP: SMS

(other connections available on request)

Operating limits:

Nominal pressure: 1600 kPa (16 bar) 232 PSI

Temperature range: -10°C to +120 °C 14 °F ila 248 °F

+140°C (SIP, maks. 30 dk.) 284 °F

Maximum flow : 220 m³/h 968 US GPM

Maximum differential head: 140 m 459 ft

Maximum speed : 3600 rpm

Motor

Triphasic induction motor with B5 flange and B3 legs, in compliance with the IEC standards,

2 poles = 3000/3600 rpm, efficiency class according to EC regulation, IP 55 protection and F-class insulation.

3 phases, 50 Hz, 230 V Δ / 400 V Y, ≤ 4 kW

3 phases, 50 Hz, 400 V Δ / 690 V Y, ≥ 5,5 kW

Options

- Pump casing with drain port.U

- Pump casing with heating chamber.

- Different types of connections.

- seal: SiC/SiC or TuC/SiC.

- Double mechanical seal.Ga

- skets: FPM or FFKM.

- Motor with other voltages, frequencies, mechanical protections, efficiencies.

- Trolley and/or control panel.

- ATEX certification.

Options of the pumps authorized to carry 3-A symbol

Connections: CLAMP-OD, CLAMP-DIN, DIN11864.

Sealing: single mechanical seal.

Mechanical seal materials: C/SiC ve SiC/SiC.

O-rings EPDM ve FPM.

Drain: vertical Clamp-OD.

Related products

Hyginox SE Hygienic Centrifugal Pumps

EFI Industrial Centrifugal Pumps

Dinfood High Capacity Centrifugal Pumps

DIN-FOOD Centrifugal Pumps, one of the High Capacity Food Processing Centrifugal Pumps, is a hygienic high capacity centrifugal pump capable of pumping up to 1000 m³/h, designed for use in the food processing, chemical and pharmaceutical industries.

It is mainly used in the beer, dairy and beverage industries and includes filtration processes. In addition, it can be used in some specific applications in the textile industry, chemistry, cosmetics and pharmaceutical industries.