Semi Welded Heat Exchanger – ParaWeld

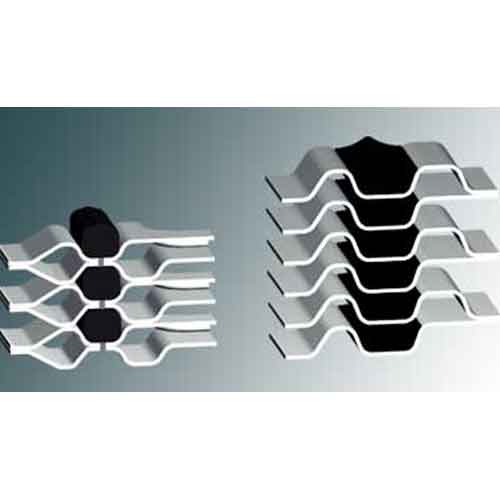

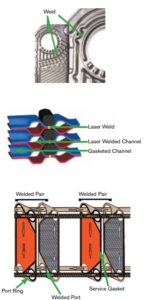

ParaWeld Semi-Welded Plate Heat Exchanger – Pairs of corrugated plates are welded. Plate pairs are separated from each other by gaskets welded plate pairs are used on the process side and normal gasket technology is used on the other side.

Semi Welded Heat Exchanger Application areas:

It has wide use in heat transfer of single and two phase fluids in refrigeration, chemical, petrochemical and industrial markets. Welded plates are designed for the use of aggressive liquids.

ParaWeld Heat Exchanger Applications:

- Flooded Evaporators

- Direct Expansion Evaporators

- Liquid Cooled Condensers

- Economizers

- Desuperheaters

- Subcoolers

- Oil coolers

Material:

Plates: AISI 316, AISI 304, Titanium, C2000 and many alloys

Gaskets: NBR, EPDM, FKM, Paramine and others

Temperature: Rubber gaskets: -45 _250 °C

Pressure: 0 – 35 bar

Heat transfer area / Capacity: Until 2000 m2

Maintenance: Welded side: Cleaning with CIP system Sealed side: Full access for cleaning and inspection.

Advantages:

- High efficiency due to counter flow

- Reducing the risk of leakage

- Thermal stress endurance

- Compact and space-saving design

- Combining different gasket materials for cost-effectiveness solutions

ParaWeld Series Plate Heat Exchanger

Maximum Performance, Minimal Space and Low Volume Hold up.

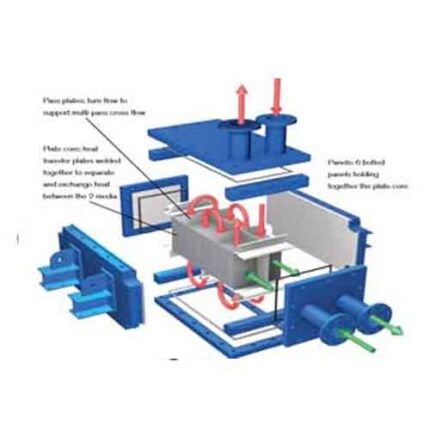

The heat transfer plates are the heart of the APV ParaWeld heat exchanger providing reliability, efficiency and economy of operation. These plates are stamped in a corrugated design pattern to induce turbulent flow, then laser welded together in pairs at the flow perimeter, minimizing liquid bypass at the edges via a patented plate design system. The refrigerant flows through this welded plate channel and the fluid to be cooled is in the gasketed channel.

The only gasketing in contact with the refrigerant are the circular port rings at the plate entrance and exit. Since the plates are welded pairs, the heat exchanger can easily be expanded should your duty requirements change in the future. Simply add more plate pairs to increase the refrigeration tonnage.

The plates are pressed and laser welded in our Goldsboro, NC, USA facility.

APV stocks 304ss, 316ss and titanium plate materials for faster delivery of new units and/or for spare parts.

Plates are also available in other alloys such as high nickel, super austenitic steels, etc, if required.

Gasket materials include neoprene and a selection of NBR’s and EPDM’s.

FDA compliant gaskets are also available for certain direct product chilling duties.

Welded pairs are aligned in a rigid, polyurethane painted carbon steel frame through the use of a top carrying bar and bottom guide bar as illustrated in figure 7. Plates have an integral hanging eye to facilitate installation and maintain proper plate alignment and support within the frame. Semi Welded Heat Exchanger – ParaWeld

APV ParaWeld Plate Heat Exchanger Versus Tubular Exchangers

APV ParaWeld Plate Heat Exchanger Versus Tubular Exchangers

Why th e APV ParaWeld provides more for your investment

Flexibility: The ParaWeld Plate Heat Exchanger allows for future expansion when your refrigeration requirements grow. Semi-welded plate pairs can easily be added to the existing heat exchanger frame.

Saves Energy: The ParaWeld Plate Heat Exchanger provides approach temperatures as close as 2oF which allows for a higher suction temperature and higher coefficient of performance than a traditional shell and tube exchanger. This will help reduce compressor size and related components of a new refrigeration system.

Less Refrigerant Needed: The higher heat transfer coefficient significantly reduces the heat transfer area needed and the narrow plate passages have a low liquid holdup. The amount of refrigerant needed in a ParaWeld Plate Heat Exchanger is only 20-30% of the capacity compared to a tubular unit. Less refrigerant means more savings on the system charge and is better for the environment.

Less Refrigerant Needed: The higher heat transfer coefficient significantly reduces the heat transfer area needed and the narrow plate passages have a low liquid holdup. The amount of refrigerant needed in a ParaWeld Plate Heat Exchanger is only 20-30% of the capacity compared to a tubular unit. Less refrigerant means more savings on the system charge and is better for the environment.

Models: The ParaWeld Plate Heat exchanger is available in models that range in connection size from 2” to 16”. A single unit can handle up to 6,400 tons of refrigeration (5,806 metric tons).

Smaller Installed Space, Easy to Maintain: ParaWeld Plate Heat Exchangers use one third less floor space and weigh 1/6th the weight of a tubular heat exchanger. The APV Plate Heat Exchanger can be maintained within the installed space and without the need to remove piping