Metal Finishing

Metal Finishing Processes

We provide quality and reliable services to you with our plate heat exchangers, mixers and other flow equipment in metal termination processes.

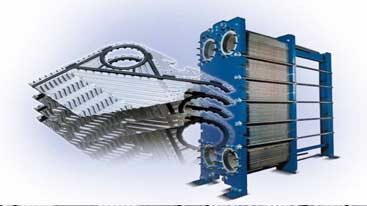

Cooling Heat Exchanger

Other Equipment That Can Be Used In The Process

Mixers

Agitators

Blenders

Stainless Steel Connection Equipment

Metal finishing processes are generally used in the metallurgical industry. These processes are carried out for various purposes such as shaping, cleaning, hardening or improving other properties of metal alloys. Heat exchangers and mixers are frequently used in metal finishing processes. Here’s an overview of how they’re used:

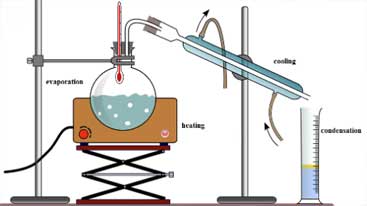

Use of heat exchangers in metal finishing processes:

- Temperature control is often required in metal finishing operations. Therefore, exchangers are used for temperature control.

- Heat exchangers are used to heat or cool the metal. For example, heat exchangers can be used to cool metal from melting furnaces or to rapidly cool metal after pouring.

- Exchangers can also be used to recover waste heat generated during the process, increasing energy efficiency.

Use of mixers in metal finishing processes:

Mixers are used to increase homogeneity in metal alloys. This ensures better mixing of the alloy components and improves the quality of the final product.

Mixers are used to increase homogeneity in metal alloys. This ensures better mixing of the alloy components and improves the quality of the final product.- Mixers also provide homogeneous distribution of additives or alloying elements into the metal matrix to accelerate chemical reactions or achieve desired properties.

- Mixers used in metal finishing operations may be specialized equipment designed for mixing metal in melting furnaces or melting pots. These mixers are generally used for adding different alloying elements or melting waste materials during the smelting process.

The use of heat exchangers and mixers in metal finishing processes increases process efficiency while also improving product quality and consistency. These equipment are widely used in the metallurgical industry and are constantly being developed and improved.