Flexible Screw Pumps

Flexible Screw Pumps; The RF pump design, which is a type of pump with a flexible impeller pump, provides it with features that distinguish it from others. It is ideal for pumping both low viscosity liquids and high viscosity liquids as well as products containing particles or gases. The self-priming RF pump is reversible and can suck from a maximum height of 5 metres. The main applications it is used in are flexible impeller pumps, generally the transfer of dairy products, edible oils, wine and beverages.

RF Flexible Screw Pumps Application

RF Flexible impeller pump, by design, equips the design with features that distinguish it from others. Ideal for pumping both low viscosity liquids and high viscosity liquids as well as products containing particles or gases.

The RF Pump’s unique design makes it reversible and self-priming. These features provide flexibility in different applications and meet various industrial needs. For example, these pumps are used in milk transfer operations, transportation of edible oils, and general transfer of wine and other beverages.

One of the most important advantages of this type of pumps is that they have the ability to suck from a maximum height of 5 meters. This expands its use in certain applications and enables it to be used effectively in a variety of industrial fields.

The usage areas of RF Pump are quite wide. In the dairy industry, hygienic transport of liquids is important and the RF Pump meets these requirements. Also, in the food industry, it is common to use this type of pumps during the transfer of edible oils. Moreover, in the beverage industry, RF Pump is preferred for pumping wine and other beverages.

From an SEO perspective, it is important to use appropriate keywords that highlight the uses and features of the RF Pump. These keywords make it easier for potential customers to find the product and help the website rank higher in search engines.

In conclusion, RF Pump is a type of flexible impeller pump and has a wide range of uses in different industrial applications. Being reversible and self-priming, it is ideal for meeting a variety of industrial needs. The ability to pump both low and high viscosity liquids makes the RF Pump a versatile solution.

The main applications are transfer of dairy products (Milk Transfer Processing), edible oils, wine applications and beverages in general.

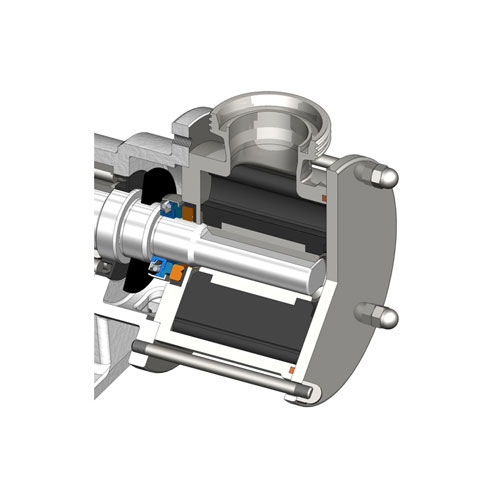

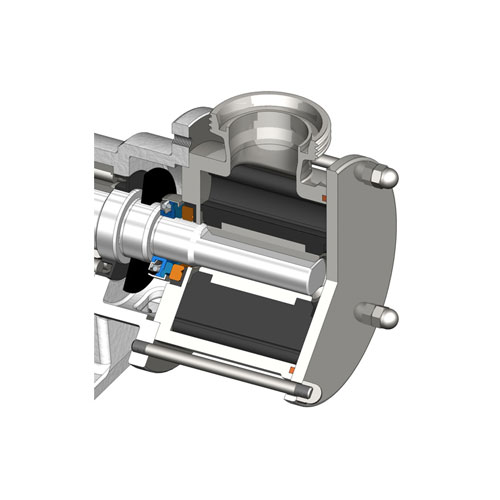

Flexible impeller pump operating principle

RF Flexible screw pumps design and features

- Bare shaft or close-coupled construction.

- Reversible and self-priming pump.

- Machined investment casting casing.

- Double flat drive of the impeller.

- External single mechanical seal.

- Easy maintenance.

Materials:

Steel parts in contact with the produ: Stainless steel AISI 316L (1.4404)

Other steel parts: Stainless steel AISI 304 (1.4301)

Lantern and bearing support: GG-22

Impeller: CR (Neoprene)

Gaskets in contact with the product: NBR

Mechanical seal:

Rotary part: Carbon (C)

Stationary part: Ceramic (Cer)

Gasket: NBR

Surface finish:

Internal: Bright polish Ra<0,8 μm

External: Matt

Connections:

- DIN 11851p

- CLAMP

- SMS

(other connections available on request)

Operating limits:

Maximum flow: 28 m³/h 132 US GPM

Maximum working pressure*: 2 – 4 bar 29 – 58 PSI

Maximum working temperature: +80°C 176°F

Maximum speed: 1450 rpm

*depending on the model

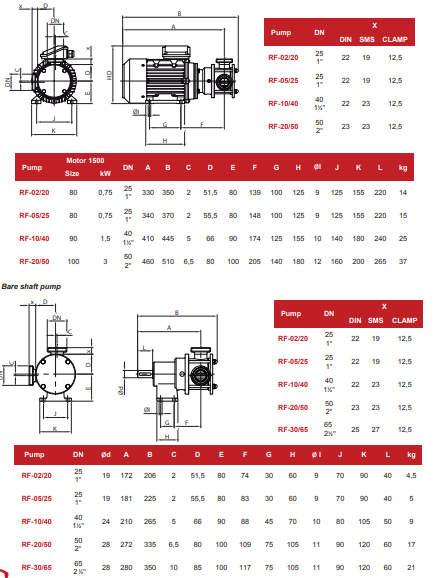

Motor

- 3 phase induction motor with B14 flange and B3 legs, in compliance with the IEC standard,

- 4 poles = 1500/1800 rpm, efficiency class according to EC regulation, IP 55 protection and F-class insulation.

3 phases, 50 Hz, 230 V Δ / 400 V Υ, ≤ 4 kW

3 phases, 50 Hz, 400 V Δ / 690 V Υ, ≥ 5,5 kW

Options

- SiC/SiC or SiC/C mechanical seals.

- Food-grade neoprene impeller (BfR).

- Other types of connections.

- Motors with other protections.

- 1000 rpm motors.

- Electric panel with 10 m cable.

- Stainless steel trolley.