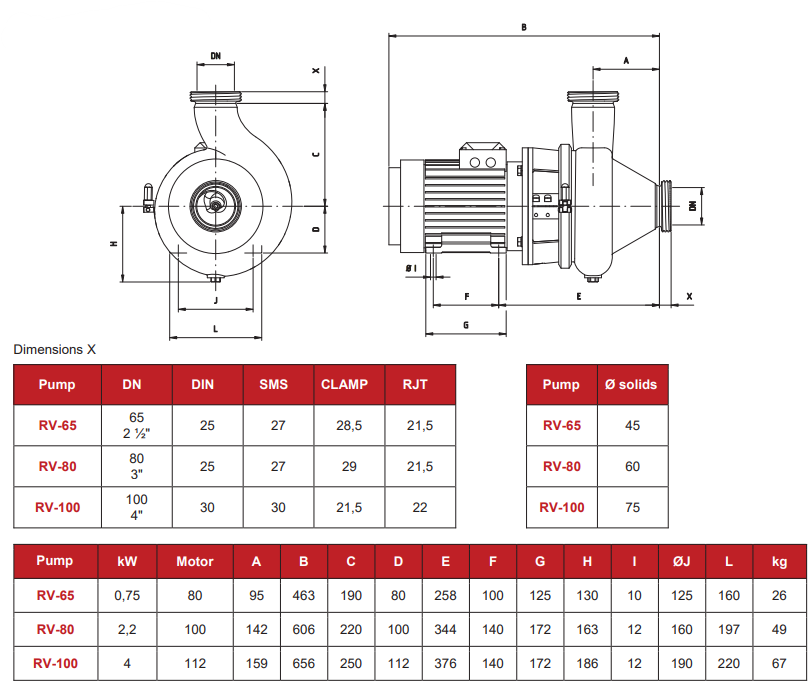

RV Helicoidal Impeller Pump

The RV centrifugal pump with helicoidal impeller is the best solution for the transfer of liquids with solid particles or medium viscosity products that cannot be pumped with an ordinary centrifugal pump. Due to the helicoidal shape of the impeller, the transfer of the product is gentle and without clogging., e.g. solid particles suspended in water (proportion: 40% to 60%). It is ideal for applications of the transfer of pieces of fruit or whole fruits, olives, mushrooms, slices of orange, vegetables, fish, etc.

Helicoidal Impeller Pumps Application

The RV RV Helicoidal Impeller Pumps with helicoidal impeller is the best solution for the transfer of liquids with solid particles or medium viscosity products that cannot be pumped with an ordinary centrifugal pump. Due to the helicoidal shape of the impeller, the transfer of the product is gentle and without clogging., e.g. solid particles suspended in water (proportion: 40% to 60%). It is ideal for applications of the transfer of pieces of fruit or whole fruits, olives, mushrooms, slices of orange, vegetables, fish, etc.

RV pumps are widely used for Wine Process Pump in wineries for the pump-over process where the high capacity and minimum destruction of the solid parts (seeds, skins, etc.) is required. The design of the pump contributes to a better extraction of tannin, the coloring matter of wine, in the phase of vinification, reducing the lees formation and, as the result, achieving high quality wines.

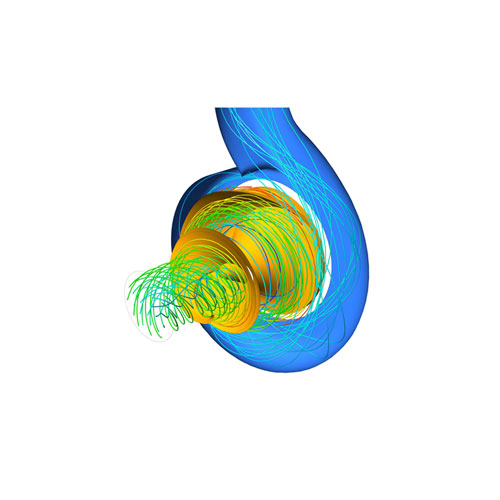

Operating principle

Due to the helicoidal shape of the impeller and to the flow optimised to avoid the obstruction of the pump, solid particles pass through the pump without being damaged.

Design and features

- Close-coupled design.

- Helicoidal impeller.

- Pump casing with drain port.

- Pump casing with volute.

- High efficiency (>70%), low power consumption.

- Motor: IEC B35, 1500 rpm, IE2.

- Mechanical seal: EN 12756 (DIN 24960 L1K).

- Connections: DIN 11851.

- Maximum particle size: ø 75mm.

Materials

Parts in contact with the product: AISI 316L

Lantern: AISI 316L

Other St.St. parts: AISI 304

Gaskets: EPDM

Mechanical seal: SiC/SiC/EPDM

Internal surface finish: bright polish

External surface finish: matte

Usage Areas of Helicoidal Impeller Pumps

Helicoidal impeller pumps are a type of pump commonly used in industrial and commercial applications. These pumps are used to transfer various liquids (usually water or chemical liquids) and can be used for various purposes in various fields. Here are some of the common uses of helical impeller pumps:

- Industry and Production: Helical impeller pumps are frequently used for the transfer and transportation of liquids in industrial processes. They can be found in a wide range of locations, from chemical plants to petrochemical plants.

- Wastewater Treatment: In wastewater treatment plants, helical impeller pumps are used to transport and process wastewater. In these facilities, they can be used at different stages of the wastewater and at different points within the facility.

- Agriculture: In the agricultural sector, helical impeller pumps can be used in irrigation systems to draw and distribute water from irrigation canals. They are also used for transporting fertilizers or agricultural chemicals.

- Maritime and Ships: In the marine industry, helical propeller pumps are used to pump and transfer ballast water on ships. They are also widely used in ship evacuation systems.

- Construction: In the construction industry, helical impeller pumps can be used to drain water in construction areas. They are also preferred for transporting mud, concrete and other construction materials.

- Food and Beverage Industry: In the food and beverage industry, helical impeller pumps are used for the transfer and processing of liquid food products. For example, they can be used to pump milk, juice, beer or other beverages.

- Power Plants: In power plants, helical impeller pumps can be used to circulate cooling water and other liquids. In thermal power plants, these pumps are often used in cooling systems.

These are just a few of the uses of helical impeller pumps, and in reality there are many more different applications. These pumps generally offer advantages such as high efficiency, low maintenance and long life, making them a preferred pump type in many industrial applications.

Use of Helicoidal Impeller Pumps in Wine Production

Helicoidal impeller pumps can be used as wine transfer pumps at various stages in wine production and provide different advantages for each of these stages. Here are some main points about the use of helical impeller pumps in wine production:

- Grape Crushing: One of the first steps in wine production is crushing or crushing the grapes. Helical impeller pumps can be used for grape crushing. These pumps can pump grape paste quickly and efficiently, ensuring it is conveniently transferred in preparation for the pressing process.

- Transfer to Fermentation Tanks: During the fermentation stage, grape juice is pumped into fermentation tanks. Helical impeller pumps can help this process happen quickly and effectively. Additionally, thanks to the low destructive properties of the pumps, they are ideal for maintaining the quality of the grape juice and yeast mixture.

- Cleaning and Sterilization: Helical impeller pumps can also be used for cleaning and sterilization of equipment and pipelines. This ensures that hygiene standards are maintained and the safety of the wine production process.

- Wine Handling and Filling: After maturation and processing, the wine is bottled and packaged. Helical impeller pumps can be used in the filling and bottling process of wine. This allows the wine to be bottled and packaged hygienically.

The main advantages of using Helicoidal impeller pumps in wine production are:

- Fast and efficient transfer: Pumps enable liquids to be transported quickly and efficiently.

- Low destructiveness: The low destructive properties of the pumps help preserve grape juice and wine quality.

- Hygienic: Helical impeller pumps help maintain hygiene standards and reduce the risk of contamination.

As a result, helical impeller pumps are one of the important equipment used in the wine production process and are used at various stages, helping to maintain wine quality and manage the production process efficiently.

Related products

Hyginox SE Hygienic Centrifugal Pumps

EFI Industrial Centrifugal Pumps

Prolac HCP Centrifugal Hygienic Pumps

Dinfood High Capacity Centrifugal Pumps

DIN-FOOD Centrifugal Pumps, one of the High Capacity Food Processing Centrifugal Pumps, is a hygienic high capacity centrifugal pump capable of pumping up to 1000 m³/h, designed for use in the food processing, chemical and pharmaceutical industries.

It is mainly used in the beer, dairy and beverage industries and includes filtration processes. In addition, it can be used in some specific applications in the textile industry, chemistry, cosmetics and pharmaceutical industries.