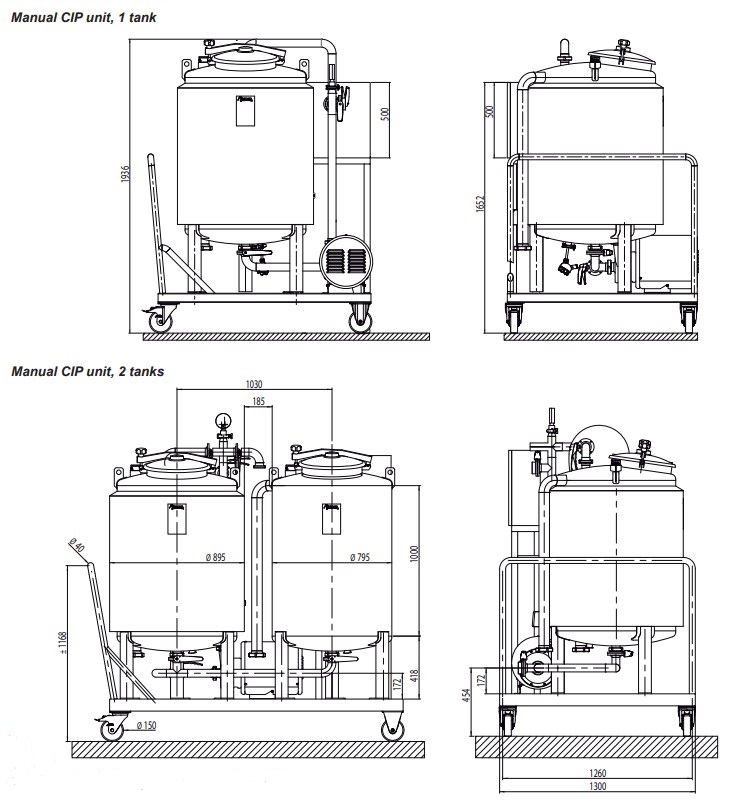

Manual Cip Units

In the pharmaceutical industry and food processing industry, cleaning should be considered as another phase of the production process. Improper cleaning causes contamination of the product and affects its quality. Manual Cip Units is a manually operated CIP unit to facilitate cleaning of small facilities, removing impurities and reducing the presence of bacteria.

Manual Cip Units are a manually operated CIP unit for small facilities that do not require a high level of automation to facilitate cleaning of facilities, remove impurities and reduce the presence of bacteria.

Manual Cip Units Application

Hygiene is an essential factor in the food processing, cosmetics and pharmaceutical industries. Cleaning is considered another stage of the production process. In the foodprocessing industry a defective cleaning causes contamination of the product and affects its quality. INOXPA offers a manually operated CIP unit for small plants, where a high level of automation is not necessary, to facilitate the cleaning of these plants, to remove the impurities and to reduce bacterial presence.

Manual Cip Units Design and Features

- AISI 304 insulated tank (500L) for cleaning solutions.

- Estampinox EFI discharge pump (4 kW).

- AISI 316 collectors with manually operated butterfly valves.

- AISI 304 frame with wheels.

- Pressure gauge at the pump outlet.

- Stainless steel electric box with temperature control.

- Tested and verified in our facilities.

- Electric heating in the tank.

- Pickled and passivated internal weldings .

Materials

Parts in contact with the product: AISI 304 / AISI 316

Other parts: AISI 304

Mechanical seal (pump): C/SiC/EPDM

Gaskets in contact with the product: EPDM

Insulation: Rock wool

Manual Cip Units Technical Specifications

- Cleaning of tanks of up to 3000 L

- Cleaing solution flow 10000 L/h

- Cleaning solution pressure 30 mwc

Options

- Piston pump for dosing of concentrates.

- Discharge pump: Hyginox SE-20 2.2 kW.

- AISI 316 tank for cleaning solution.

- CIP return fIlter with 0.5 mm screen.

- AISI 304 water tank 500 L.

- CIP return pump: ASPIR A-80 3 kW.

- Flow detector

Related products

CIP Manual Mobile System

Abh In-Line Flotation Unit

Winebrane – Dealcoholisation Technology

Winebrane Dealcoholisation Technology is a system for accurately managing divided gas concentrations in wine. The most common applications are de-carbonation, de-oxygenation, carbonation and adjustment of CO2 in white, red and rosé wines. The system is installed before the bottling stage to adjust the gas concentration of wine before its storage or bottling process.

Pasteuriser

Pasteuriser (HTST) is designed for the thermal treatment of milk and dairy products as well as other food products as soft drinks and juices. The process destroys pathogenic microorganisms by heating the product to a moderately high temperature for a brief period. Other working parameters to be consulted.