NHS Vertical Agitator Application

NHS Vertical Agitator can be used for mixing, dissolving and maintenance operations where light to moderate mixing is required. This mixer is designed for the food processing, cosmetics (such as sunscreen production) and pharmaceutical industries and is provided with the most suitable coating for each industry.

The NHS Vertical Agitator can be used in tanks of up to 10.000 L with products of medium to high viscosity.

Operating principle

The agitators are installed inside the tank either centrally with current deflectors (baffles), or offset so that the position itself prevents the rotation of the mixed product. The rotation of the propeller makes the fluid flow to the bottom and then up to the surface of the product along the walls of the tank. The effect is enhanced if the bottom of the tank is curved.

Design and features

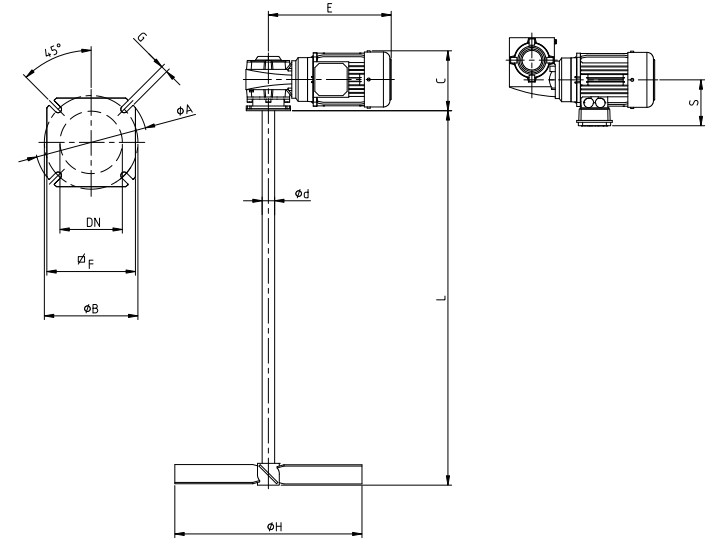

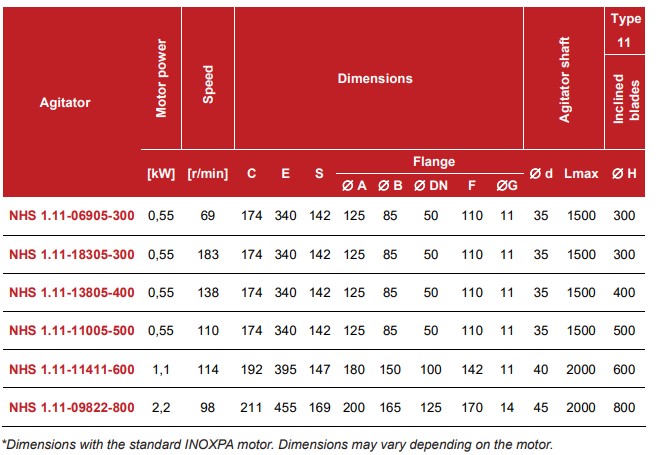

- Vertical agitator.

- Sealing: splash ring and lip seal.

- Propeller fixed to the shaft by Allen cap screws.

- Worm gear motor with smooth surfaces and food-grade oil:

- IEC, IP55, F-class insulation.

- Propeller with 4 inclined blades (T11).

Materials

- Parts in contact with the product: AISI 316

Lip seal: NBR

Gear housing: aluminium

Surface finish: Ra < 0.8 μm

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions