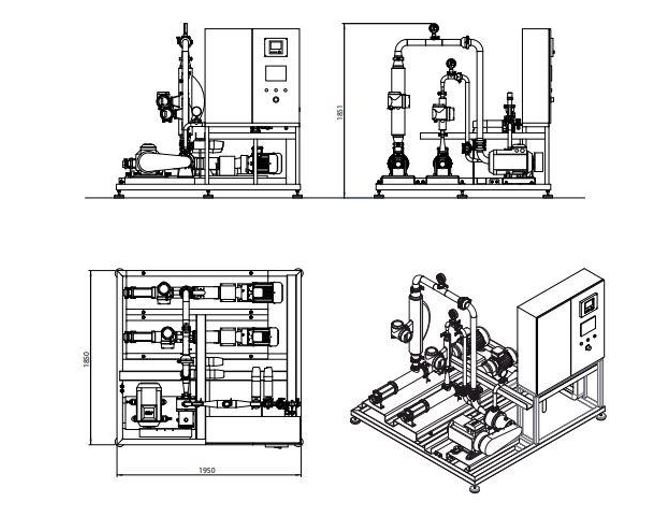

SLES Dilution System

SLES Dilution System, Sodium Lauryl Ether Sulphate (SLES) is a surfactant commonly used in the manufacture of cleaning products, soaps, shampoos and even toothpaste.

SLES Dilution System; It is usually given to manufacturers at concentrations above 70% of liquids. Due to its physical properties, this concentrated solution is difficult to handle and must be diluted below 27% before processing.

Working Principle of SLES Dilution System

Concentrated SLES and water are continuously dispersed and mixed as they enter the high shear mixer. The mixer’s stator with several rows of concentric teeth ensures complete in-line dilution.

The equipment has mass flow meters that feedback the flow of each fluid to the controller, achieving the desired concentration of SLES at 27%. Optionally, minority products can be dispensed into waterline products such as preservatives or pH regulators.

Technicial Specifications

- Pump : Monopump

- Mixer : Multi-tooth Mixer

- Valve : Butterfly Valve

- Material :

- Parts in contact with the product: AISI 316L

- Other steel parts: AISI 304

- Gasket in contact with the product:/o-ring EPDM-NBR

- Enclosure: AISI 304

- Flowmeter : Mass AISI 316

- Mechanical Seal : Pump C/Cer/NBR

- Mixer: C/SiC/EPDM

- Electrical Control: PLC panel with 9” inch screen

- Connection : Clamp (Other connections are available upon request.)

Related products

CIP Manual Mobile System

Barrel Emptying Systems

Abh In-Line Flotation Unit

Winebrane – Dealcoholisation Technology

Winebrane Dealcoholisation Technology is a system for accurately managing divided gas concentrations in wine. The most common applications are de-carbonation, de-oxygenation, carbonation and adjustment of CO2 in white, red and rosé wines. The system is installed before the bottling stage to adjust the gas concentration of wine before its storage or bottling process.