Barrel Emptying Systems

Sesinoks Barrel Emptying systems are hygienic system used for low and high viscosity products in the food, beverage, chemical, cosmetic and pharmaceutical industries. Sesinoks Barrel Emptying System successfully discharges the material in the drum with less than 1% product left.

Barrel Emptying Systems Application

Sesinoks Barrel Emptying System is a hygienic product to be used in food&beverage, chemical, cosmetic and pharmaceutical industries for low or high viscosity products.

Working Principle of Drum Unloading System

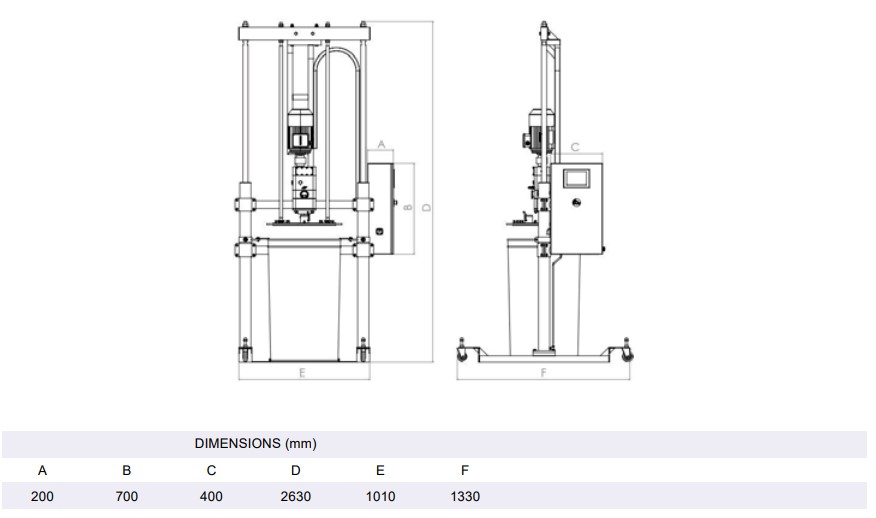

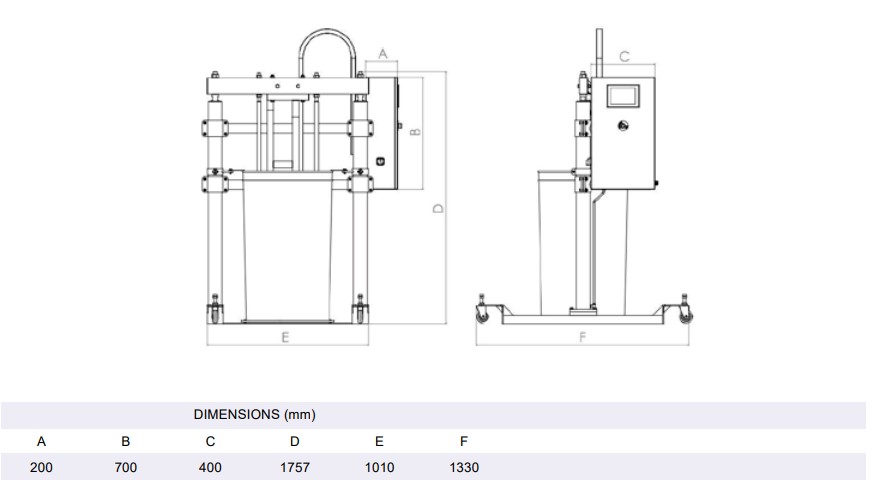

The follower plate, with soft lip sealing , presses tightly against the wall of the barrel ensuring almost complete empytying of the container. The linear guide rail system, used to adjust the height of the pump.can be easily cleaned and accommodates various container sizes.

System works on base of volumetrically conveying Sesinoks Progressing Cavity Pump, which creates vacuum under the follower plate and that vacuum causes certain pressure on the material in barrel, so that pump can have a constant suction.

Like this, system empties barrel successfully with less than 1% remaining material inside.

Barrel Unloading Systems Design and Features

- Capacity : 4,5 – 5 tons / h

- Pressure : 5 bar

- Viscosity : 3500 cpu

- Reducer : 3kw 322 rpm

Materials

Parts in contact with the product: AISI 316

Other steel parts: AISI 304

Gaskets: EPDM or FPM

Shafts: Stainless Steel

Shaft Seal: Single, Double Mechanical Seal

Surface Finish: Ra<0.8 μm

Connections: DIN 11851, SMS, ISO, Clamp

Base Plate: Stainless Steel

Coupling Guard: Stainless Steel

Barrel Discharge System Operating Limits

Maximum differential pressure: 12 bar

Maximum working pressure: 12 bar

Temperature range (EPDM): -10 °C to +120 °C

Temperature CIP, max. 30 minutes: +140 °C

Maximum speed: 3000rpm (50hZ)

Barrel Unloading Systems

What is a barrel emptying device?

Drum discharge apparatus is a device that enables the safe and effective discharge of liquid or powder products from large barrels, usually designed for industrial or commercial uses. These apparatus are generally used for the transportation and handling of various products such as chemicals, oils, solvents, foodstuffs.

Drum emptying apparatus consists of several main components:

- Pumps or screws: Used to pump out or draw out the liquid or powder product in the barrel.

- Connection parts: They are tightly mounted on the top of the barrel and ensure safe transfer of the product.

- Control valves: Used to control the flow rate and regulate the process.

- Safety features: They may contain safety valves or sensors to prevent leaks or leaks of the product being transported.

Drum unloader operation generally follows these steps:

- The Drum is placed on the bottom and the Drum Discharge Pump is placed on the top of the apparatus and the connections are securely attached.

- Drum Discharge Pumps or screws begin to suck the liquid or powder product inside the drum.

- While the product is pumped or discharged to its target location, the flow rate and amount are regulated by control valves.

- When the process is completed, the barrel unloading apparatus is removed and the barrel is made ready for another process.

These apparatus are designed to ensure the safe and hygienic transfer of products and should be used in accordance with occupational safety standards. In addition, a suitable barrel unloading apparatus should be selected according to the characteristics of the transported substance.

Related products

CIP Manual Mobile System

Abh In-Line Flotation Unit

Winebrane – Dealcoholisation Technology

Winebrane Dealcoholisation Technology is a system for accurately managing divided gas concentrations in wine. The most common applications are de-carbonation, de-oxygenation, carbonation and adjustment of CO2 in white, red and rosé wines. The system is installed before the bottling stage to adjust the gas concentration of wine before its storage or bottling process.

Pasteuriser

Pasteuriser (HTST) is designed for the thermal treatment of milk and dairy products as well as other food products as soft drinks and juices. The process destroys pathogenic microorganisms by heating the product to a moderately high temperature for a brief period. Other working parameters to be consulted.