IBC Tank Agitator Application

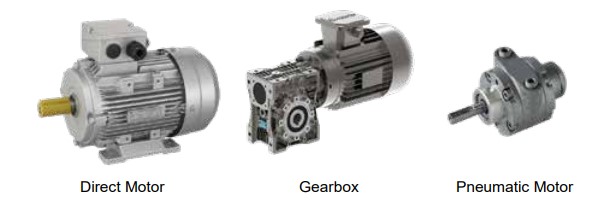

IBC tank agitators are vertical agitators with either direct or geared motor. It can be used in mixing, dissolution and maintenance processes.

This agitator is designed for almost all industrial process such as chemical, cosmetic and container whose volume are 800 or 1000 L.

IBC agitators can be designed according to requirements of process and the feature of the liquid to be mixed. Motor power and type of the propeller can be altered with considering your needs.

IBC Tank Mixer Operation

IBC agitators are installed on the top of the plastic transportable (IBC) containers centrally with a folding propeller. The rotation of the propeller makes the product flow to the bottom and then up the surface along the walls of the IBC tank. At the same time, product is mixed homogeneously without clumps and prohibit the substances from settling down to the bottom.

The reliable frame made of stainless steel is placed on the IBC tank and securely fixed with a fixation clamps on the construction of the container.

As standart the IBC agitator is supplied with an eye bolt for lifting the agitator using a hoist, and gap on modules are available for lifting the agitator using a forklift truck.

Options

- Adjustable Speed Control with VFD

- Hopper

- Base Frame

- Motor Shroud

- Pneumatic Drive

- ATEX model available

Materials

Materials

Propeller: AISI 316 SS

Shaft: AISI 316 SS

Base Frame: AISI 304 SS

Hopper: AISI 304 SS

Sealing: NBR

Other materials: Please consult your supplier

Motor Type

Motor type is selected according to the features of the liquid to be mixed. One of the most important issue of selecting motor is viscosity of the liquid. According to viscosity , motor power and speed can be adjusted.

Related products

BCI Vertical Agitator

BCI Vertical Agitator are used in industries such as food, cosmetics and chemistry. They have a reinforced bearing. Different propeller options are available according to the application process. All surfaces in contact with the product are made of A316 stainless steel and are electropolished. It can be mixed in the viscosity range of 1-1000 cps.

PBC Portable Agitator

PBC series mixers are clamped and vertical and direct motorized mixers. These mixers can be used for mixing, dissolving, dispersing and maintenance operations when very strong and fast agitation is required, usually in the food processing, cosmetics, pharmaceutical or chemical industries. PBC Portable Mixers can be installed in small tanks up to 1,500 liters to work with low viscosity products.

SMX Side Entry Agitator

Side Entry Agitators are an economical and effective solution for storage tanks in the food, pharmaceutical and cosmetic industries. The most important application is the maintenance and homogenization in large volume tanks of low viscosity products such as wine, oil, milk, beer, alcohol, etc.

CPG Side Entry Agitator

NBI Vertical Agitators

NHS Vertical Agitator

The NHS Vertical Agitators are vertical agitators with worm gearmotor. They can be used in mixing, dissolution and maintenance processes where a mild to medium mixing is required. This agitator is designed for the food-processing, cosmetic and pharmaceutical industries and it is provided with the most suitable finish for each industry.