LR/LM Bottom Side Entry Agitator

The Bottom Side Entry Agitator – LR/LM are adapted to the tanks with an angle from the side. They are used in sectors such as food, cosmetics and chemistry. They have a reinforced bearing. Different propeller options are available according to the application process. All surfaces in contact with the product are made of A316 stainless steel and are electropolished. It can be mixed in the viscosity range of 1-1000 cps.

LR/LM Bottom Side Entry Agitator Application

The bottom side entry agitators are used in process and storage tanks in the applications of the food-processing industry. The main application is agitation of low viscosity products like wine, oil, milk, beer, alcohol, etc. in large volume tanks.

Bottom Side Entry Agitator – LR/LM Operating Principle

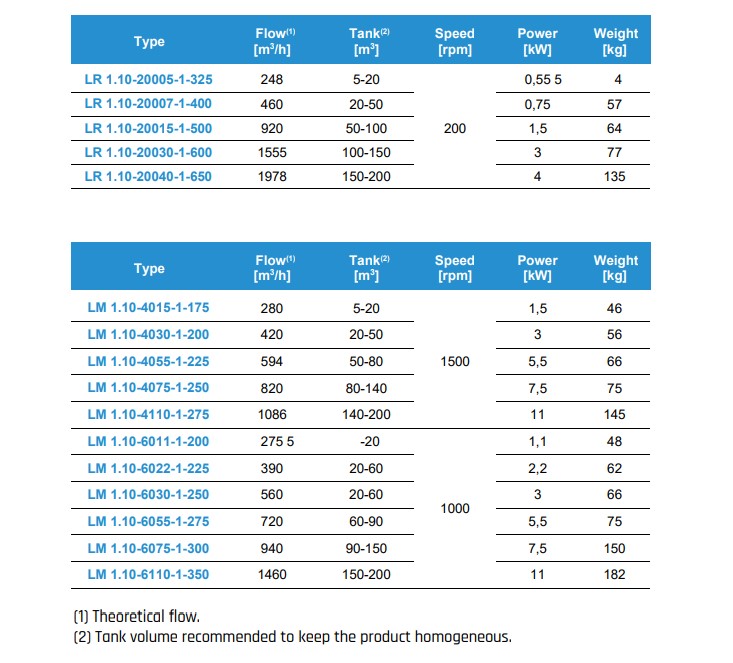

The LR agitators are driven by geared motors and the LM agitators are provided with direct motors.

These agitators are installed in a slanted position. The rotation of the propeller creates a flow that impells the product to the bottom of the tank and then raises up to the surface along the wall opposite to the agitator. The effect is promoted if the bottom is rounded.

The agitator is installed decentralized to enhance the circular flow. Thus,

Design and Features

Bottom side entry agitator

- Internal mechanical seal: EN12756 (DIN 24960 L1K).

- Economical for use in large volume tanks.

- Robust and sanitary design.

- Easy maintenance.

- he propeller fixed to the shaft by means of a threaded

- connection and a gasket.

- Helical geared motors with food-grade oil.

- Motor: 3 ph, 230/400 V, 50 Hz, IP55, 1500 rpm.

- Marine propeller (Type10).

Materials

- Parts in contact with the product : AISI 316L

- Lantern and bearing support : GG 15

- Mechanical seal : C/SiC/EPDM

- Gaskets : EPDM

- Surface finish : Ra ≤ 0,8 Μm

Options

- SiC/SiC mechanical seal.

- Double mechanical seal.

- Gaskets: FPM.

- Safety packing.

- High flow (Type 19) propeller for LR agitators.

- St.St. motor shroud.

- Motors with other protections.

- ATEX (LR) model available.

Related products

BCI Vertical Agitator

BCI Vertical Agitator are used in industries such as food, cosmetics and chemistry. They have a reinforced bearing. Different propeller options are available according to the application process. All surfaces in contact with the product are made of A316 stainless steel and are electropolished. It can be mixed in the viscosity range of 1-1000 cps.

PBC Portable Agitator

PBC series mixers are clamped and vertical and direct motorized mixers. These mixers can be used for mixing, dissolving, dispersing and maintenance operations when very strong and fast agitation is required, usually in the food processing, cosmetics, pharmaceutical or chemical industries. PBC Portable Mixers can be installed in small tanks up to 1,500 liters to work with low viscosity products.

SMX Side Entry Agitator

Side Entry Agitators are an economical and effective solution for storage tanks in the food, pharmaceutical and cosmetic industries. The most important application is the maintenance and homogenization in large volume tanks of low viscosity products such as wine, oil, milk, beer, alcohol, etc.

CPG Side Entry Agitator

NBI Vertical Agitators

NHS Vertical Agitator

The NHS Vertical Agitators are vertical agitators with worm gearmotor. They can be used in mixing, dissolution and maintenance processes where a mild to medium mixing is required. This agitator is designed for the food-processing, cosmetic and pharmaceutical industries and it is provided with the most suitable finish for each industry.