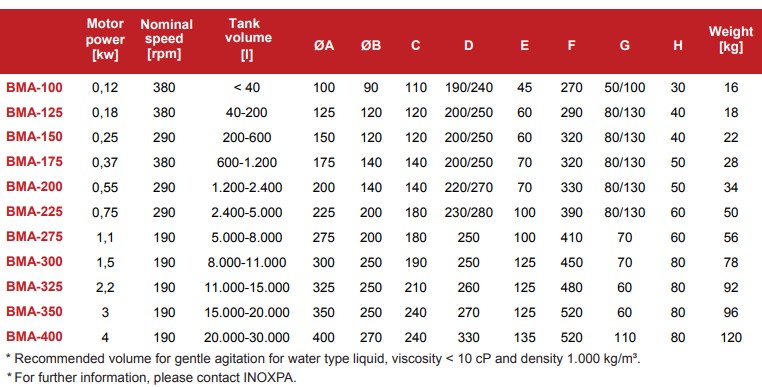

BMA Magnetic Agitator

The BMA magnetic agitator is a highly hygienic solution for dispersion, dissolution, homogenization and mixing applications in the pharmaceutical and biotechnology applications and food processing industries.

BMA Magnetic Agitator Application

The range of Magnetic Agitator BMA is a highly hygienic solution for the applications of dispersion, dissolution, homogenization and mixing in the pharmaceutical, biotechnological applications and food-processing industries.

Due to the magnetic coupling they are especially useful because they avoid any possible contact of the product with the atmosphere.

BMA Magnetic Agitator Operating principle

When solids or liquids are added into the vortex created by the Magnetic Drive Agitators, they are transferred straight to the rotor.

The rotor transforms the axial movement of the medium into a radial acceleration from the centre of the rotor towards the wall of the vessel.

The added medium is well distributed ensuring a homogeneous mixing of all the volume.

It is strongly advised to assemble the agitator in eccentric position in order to minimize vortex and to avoid the installation of deflectors.

Magnetic Drive Agitators Design and features

- Magnetic coupling. No leakage.

- Designed for cleaning and sterilization (CIP and SIP).

- Very low particle generation.

- Bottom mounted. Excellent for suspensions.

- Practical when there is no much space at the top of the tank.

- Easy disassembly: neither lifting device nor special maintenance support required.

- Autoclavable rotor.

Materials

- Parts in contact with the product AISI 316L

- Bushing SiC

- O-ring FEP for models up to BMA-225

- EPDM for other models

Related products

PBC Portable Agitator

PBC series mixers are clamped and vertical and direct motorized mixers. These mixers can be used for mixing, dissolving, dispersing and maintenance operations when very strong and fast agitation is required, usually in the food processing, cosmetics, pharmaceutical or chemical industries. PBC Portable Mixers can be installed in small tanks up to 1,500 liters to work with low viscosity products.

LR/LM Bottom Side Entry Agitator

The Bottom Side Entry Agitator - LR/LM are adapted to the tanks with an angle from the side. They are used in sectors such as food, cosmetics and chemistry. They have a reinforced bearing. Different propeller options are available according to the application process. All surfaces in contact with the product are made of A316 stainless steel and are electropolished. It can be mixed in the viscosity range of 1-1000 cps.

SMX Side Entry Agitator

Side Entry Agitators are an economical and effective solution for storage tanks in the food, pharmaceutical and cosmetic industries. The most important application is the maintenance and homogenization in large volume tanks of low viscosity products such as wine, oil, milk, beer, alcohol, etc.

CPG Side Entry Agitator

NBI Vertical Agitators

NHS Vertical Agitator

The NHS Vertical Agitators are vertical agitators with worm gearmotor. They can be used in mixing, dissolution and maintenance processes where a mild to medium mixing is required. This agitator is designed for the food-processing, cosmetic and pharmaceutical industries and it is provided with the most suitable finish for each industry.