CPG Side Entry Agitator

CPG Side Entry Agitator is a side entry mixer for the Winemaking industry. Specially designed for Wine Tanks, these are mixers with the impeller feature that opens automatically when the mixer is running. It is an economical and practical solution with its ability to be used in many tanks due to its mobile nature. They are produced in 3 different capacities of 20m3 – 25-50m3 and 50-100 m3.

CPG Side Entry Agitator Application

- For the winemaking industry.

- Maintenance of solids in suspension.

- Coupage (wine blending).

- Gasification (SO or CO ).

- Temperature homogenisation.

CPG Side Entry Agitator Operating Principle

The design of the agitator is based on the shaft that slides through a full bore valve into the tank and a propeller that opens automatically when started. The agitator shaft is provided with a C/St.St./EPDM mechanical seal.

Design and features

- The CPG wine agitators are designed for installation in tanks full of product by means of a full bore valve without losing product and without special tools.

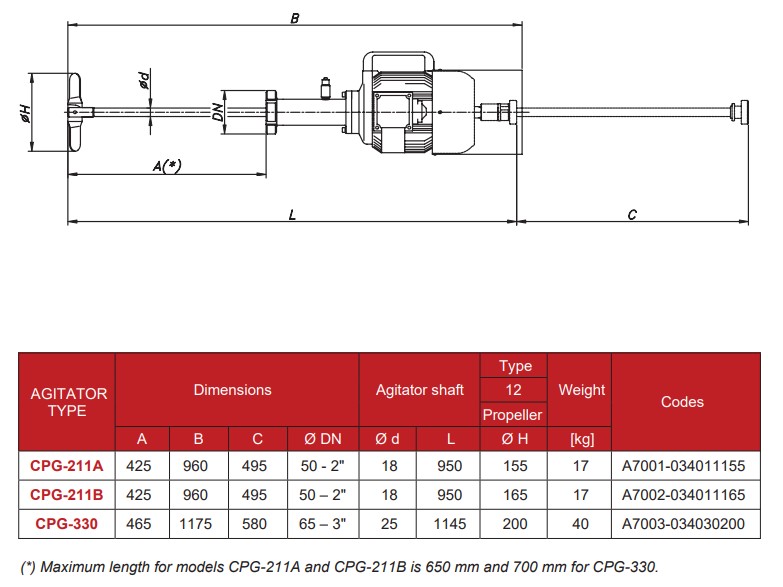

- The standard mixing element is folding propeller type 12.

- Electric motor 3 ph, 400 V. , 50 Hz, IP 55, 1450 rpm.

- Manual deaeration valve.

- Standard connections DIN 11851.

Options

- Stainless steel trolley.

- Valve for product injection, drainage or sampling.

- Mechanical seal SiC/SiC/FPM.

- Female connection to the motor.

- Control panel and protection in compliance with the EC standards.

- Special shaft length.

- Connections: FIL ISO 2853, SMS, Clamp ISO 2852,

- RJT BS-1864,Garolla.

Related products

BCI Vertical Agitator

BCI Vertical Agitator are used in industries such as food, cosmetics and chemistry. They have a reinforced bearing. Different propeller options are available according to the application process. All surfaces in contact with the product are made of A316 stainless steel and are electropolished. It can be mixed in the viscosity range of 1-1000 cps.

PBC Portable Agitator

PBC series mixers are clamped and vertical and direct motorized mixers. These mixers can be used for mixing, dissolving, dispersing and maintenance operations when very strong and fast agitation is required, usually in the food processing, cosmetics, pharmaceutical or chemical industries. PBC Portable Mixers can be installed in small tanks up to 1,500 liters to work with low viscosity products.

SMX Side Entry Agitator

Side Entry Agitators are an economical and effective solution for storage tanks in the food, pharmaceutical and cosmetic industries. The most important application is the maintenance and homogenization in large volume tanks of low viscosity products such as wine, oil, milk, beer, alcohol, etc.

NBI Vertical Agitators

NHS Vertical Agitator

The NHS Vertical Agitators are vertical agitators with worm gearmotor. They can be used in mixing, dissolution and maintenance processes where a mild to medium mixing is required. This agitator is designed for the food-processing, cosmetic and pharmaceutical industries and it is provided with the most suitable finish for each industry.