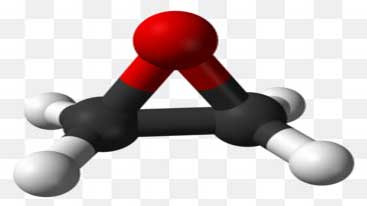

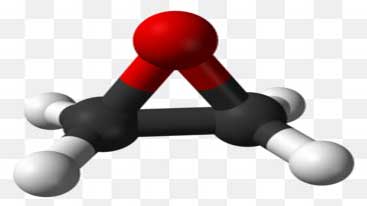

Organic Acid Synthesis; Most of the organic acids found in plants are either free or in the form of salts or esters. It is the basic material in the production of polyester and solvent and organic acids are classified according to the number of carboxyl groups in their structure. Sesinoks is your quality and reliable solution partner for organic acid synthesis processes with our plate heat exchangers, flow equipment and wide range of products.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

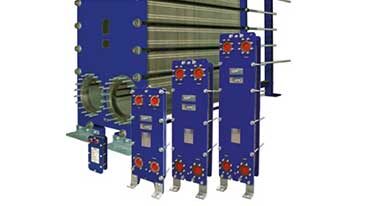

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions

Organic acid synthesis is a process in which organic acids are produced through chemical reactions of organic compounds. This synthesis has a wide range of uses in various industrial applications, from the pharmaceutical industry to the food industry. Heat exchangers used in organic acid synthesis are generally used to ensure temperature control and energy efficiency.

Organic acid synthesis is a process in which organic acids are produced through chemical reactions of organic compounds. This synthesis has a wide range of uses in various industrial applications, from the pharmaceutical industry to the food industry. Heat exchangers used in organic acid synthesis are generally used to ensure temperature control and energy efficiency.