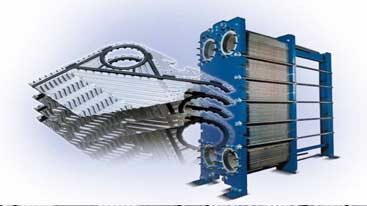

Acid Cooling Processes; Acids have corrosive and penetrating properties. Our plate heat exchangers used in the chemical industry provide you with longer lasting and higher quality services with the plate and gasket selections made considering these harmful effects of acids on the material.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions

Acid cooling exchangers:

Acid cooling exchangers: