Solution Cooling And Heating

Solution Cooling and Heating Processes

Solution Cooling and Heating; We provide reliable and quality services to you with our wide range of products, including plate heat exchangers, mixers and other flow equipment that can be used in processes in solution cooling and heating processes.

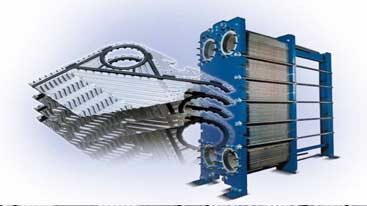

Cooling Heat Exchanger

Other Equipment That Can Be Used In The Process

Mixers

Agitators

Blenders

Stainless Steel Connection Equipment

Use of Heat Exchanger in Solution Cooling and Heating Processes

Solution Cooling And Heating

Solution heating and cooling are important parts of many finishing processes. The temperature of the solutions affects cleaning effectiveness, electron deposition rates, ability to produce heavier anodic coatings on aluminum (hard anodizing), and many other chemical processes involved in finishing. Heat exchangers are among the most common equipment for controlling the temperatures of solutions.

Solution Heating and Cooling Heat Exchangers

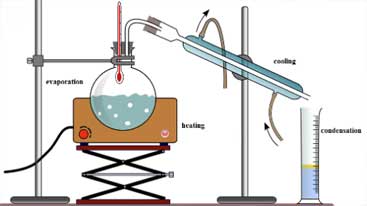

Heat exchangers can be used to heat or cool a solution. They work by circulating a liquid (or vapor) that is hotter or cooler than the process solution. In the simplest installations, liquid circulates through pipes, coils or plate-type units immersed in the process solution. As vapor or liquid circulates through submerged pipes, plates, or coils, heat is exchanged and the process solution becomes hotter or colder.

In larger installations external heat exchangers can be used. They take up very little space in the process tank because they recirculate process solutions through an external heat exchanger using a pump. The tubes in the external heat exchanger that circulate the process solution are surrounded by a shell or plate and frame enclosure containing liquid that is cooler or hotter than the process solution. This fluid is also recirculated using a pump. If the goal is to heat the process solution, heat is transferred from the water or other liquid in the shell to the process solution in the tubes. If the goal is to lower the process-solution temperature, heat is transferred from the process solution to the surrounding coolant.

For both types of heat exchangers (external or internal), construction materials are important. Plating and anodizing solutions can be very corrosive. Depending on the chemical composition of the process solution, a variety of metals and plastics may be suitable, from mild steel to titanium, graphite, tantalum and fluoropolymers.

Sizing heat exchangers requires calculations based on the specific heat of the solution, the heat transfer rate of the metal or plastic used in construction, evaporation losses.