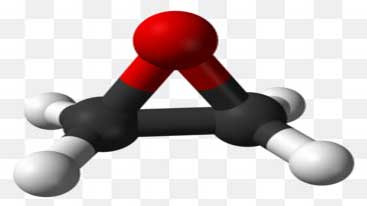

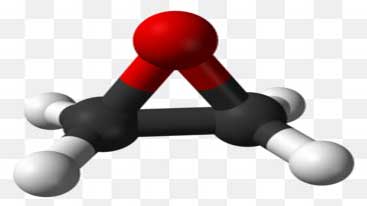

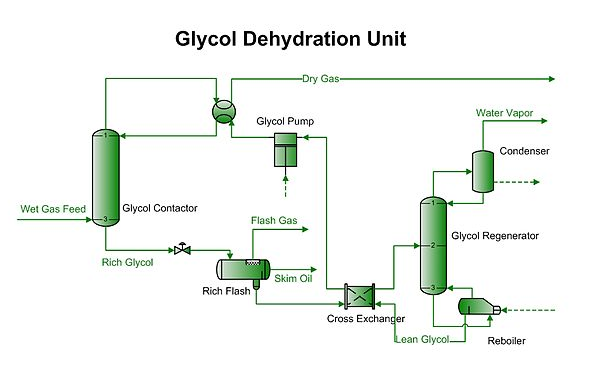

During the dehydration process, small molecules combine and form larger molecules and water is released during this time. The purpose of glycol dehydration is to separate water in natural gas, natural gas liquids in industry. Water separation from NGL fluids with glycol dehydration is the most common and economical method used in the industry.

Stainless Steel Products

Stainless Steel Products Mixing

Mixing Pumps

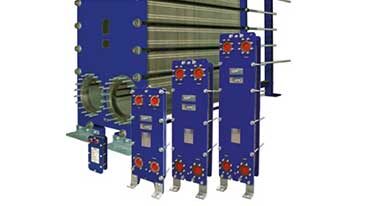

Pumps Heat Exchangers

Heat Exchangers System Solutions

System Solutions

Exchangers play an important role in the glycol dehydration process and are often used for:

Exchangers play an important role in the glycol dehydration process and are often used for: