Paper Coating

Preparation of Paper Coating

Paper and board grades are sometimes coated to improve the printability, visual properties, or functionality of the sheet. Coating formulas typically contain three categories of ingredients: pigments, binders and additives.

Pigments used in paper and board coatings govern the final optical and printing properties of the sheet. They do this by providing brightness, whiteness, smoothness, and opacity. Binders adhere the pigment particles to each other and to the sheet, and additives either assist in the coating process or enhance sheet properties.

Traditionally, coatings were based on clays such as china clay (kaolin) and bentonite, but calcium carbonate is more common in modern paper coatings. Other materials are also used to achieve certain properties. These include:

- Talc – for smoothness.

- Silica – for applications that require good water absorption – eg ink jet paper.

- Titanium Dioxide – for whiteness and opacity.

- Resins – control of ink absorption rate.

Process

Some coating mixtures contain 10 or more ingredients. A typical print-grade coating formula might contain 83% pigment, 13% binder and 4% additives (by percent of dry weight). These ingredients are typically dispersed in water.

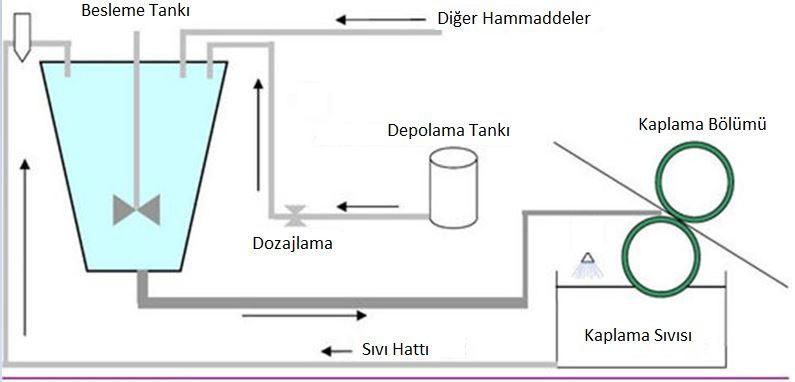

Some papermakers prepare the slurry themselves by dispersing the powder into water using conventional agitation. Long mixing times may be required to produce each batch. Fundamental coating preparation can be summarized as follows:

- The slurry is diluted to the required working strength and kept in a storage tank

- The binder is prepared separately before mixing with the slurry.

- At this stage, wax, colorant, etc. other additives such as can be added.

- The finished coating can be passed through a filter to remove lumps or impurities.

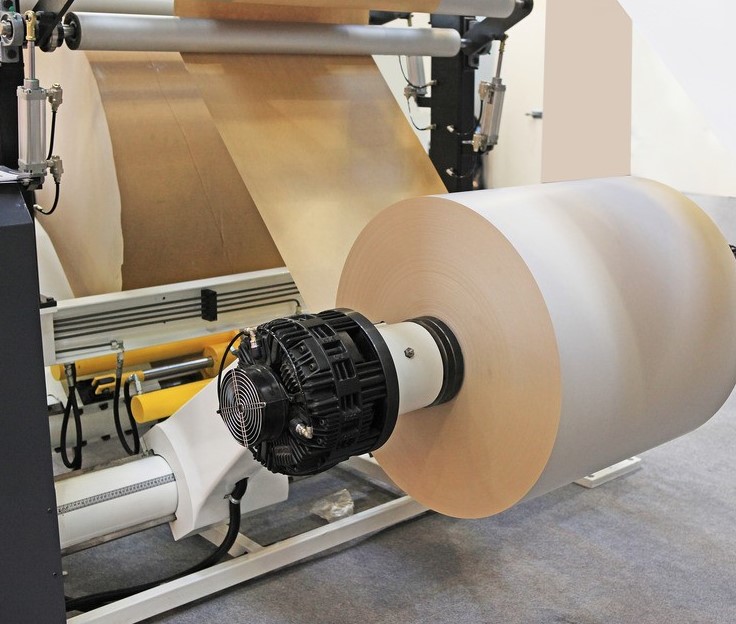

- The coating is then applied to paper or cardboard using a number of methods.

Agglomerates and impurities in the clay slurry used in the paper industry cannot be broken down by simple mixing. They are transferred to the paper coating machine and cause defects on the coating surface.

Our high-shear mixers, which are designed to overcome such problems, allow you to make a fully homogeneous mixture with high efficiency with its rotor-stator operation.